KNOWLEDGE

What You Need to Know About Packaging Tubes

Flexible and squeezable. Tubes have become a common packaging choice in a variety of industries, but have become especially popular in the personal care industry. Tubes are most commonly a round shape, but are extremely versatile with size, barrier, and dispensing options. With such versatility, tubes are a popular choice for packaging products ranging from beauty creams to industrial chemicals.

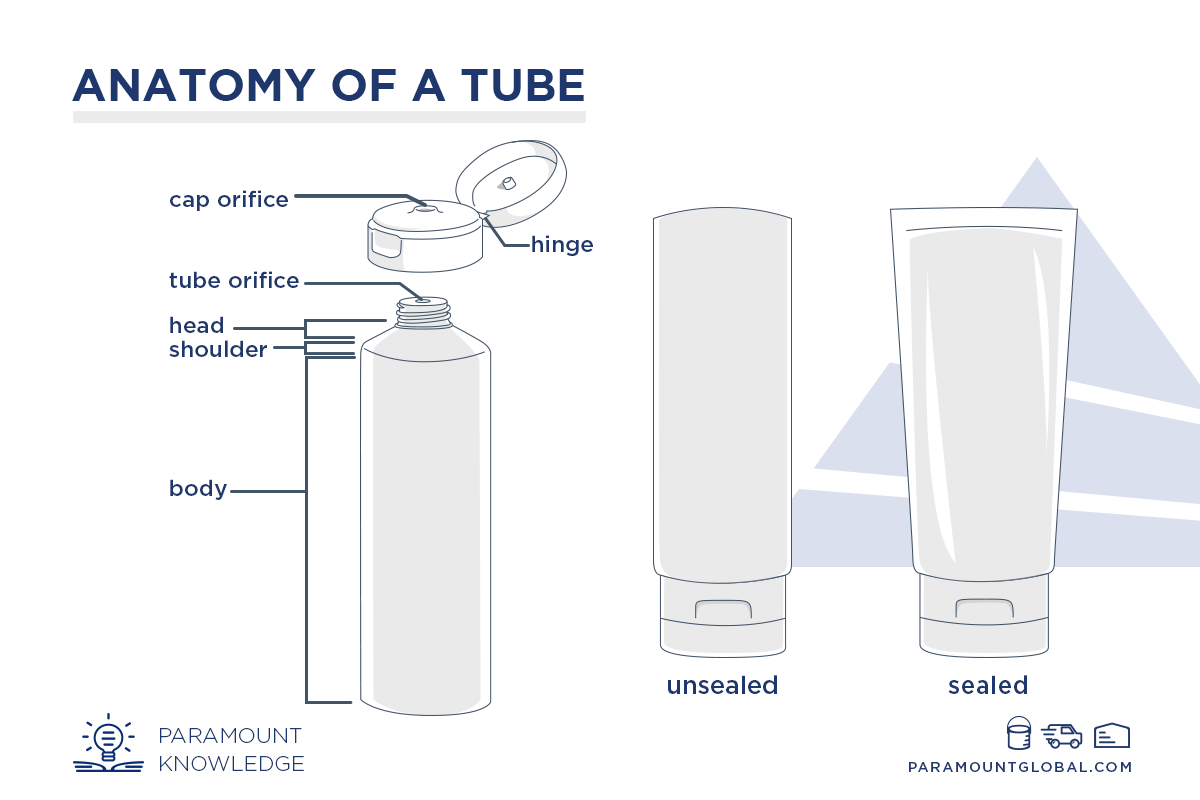

All tubes have an orifice, head, shoulders, and body. Length and width of the body can vary depending on the size of tube needed. Also a range of orifice sizes are available depending on how quickly you would like product to be dispensed and the viscosity of the product. For example, less viscous (more watery products) would work better with a smaller orifice in order to prevent too much product being dispensed at once while more viscous (such a thicker, creamy, or more gummy type products) would need a larger orifice.

Tubes are most commonly made from plastic, aluminum, or a laminate (a mixture of both materials) to provide additional barriers to protect the product.

Aluminum

A traditional tube material that is still used today. They are often used for artist paints, adhesives, toothpaste, and other viscous liquids. Aluminum tubes can be referred to as ‘collapsible’ since thare more rigd and can dent.

Plastic

Plastic tubes are only made from plastic and are mono-layer. As a single layer, it is the most cost effective to produce, but will only work with products with non-active chemicals.

Laminate

Laminate tubes typically consists of a hybrid of materials for stronger barrier properties. There are different types of laminate tubes and are divided based on the materials the tube is made of. The most common types of laminate tubes are: ABL, PBL, and APT.

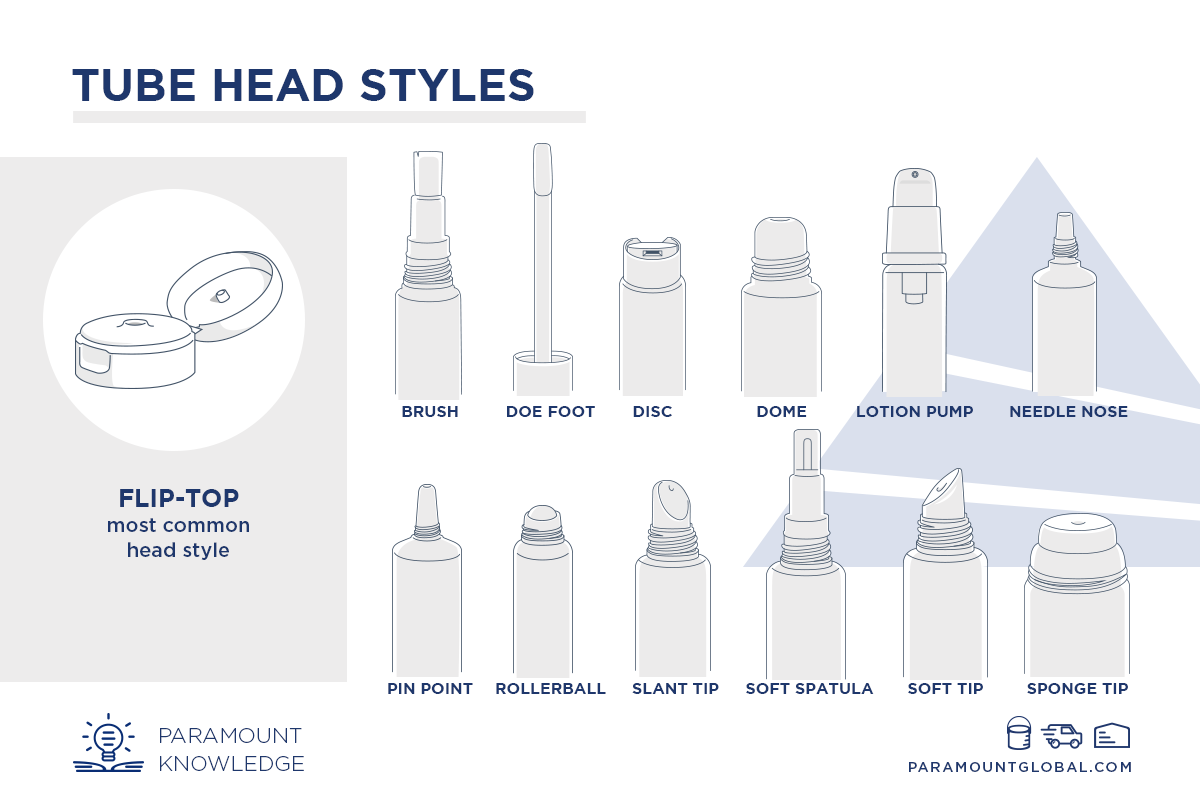

Depending on the product and how it needs to be dispensed, there is a wide selection of tube heads to pair with the tube body to fit the product’s needs. Flip-top caps are most commonly used across many industries, but you will discover a much more diverse head style in the personal care industry to optimize dispensing product. Below is a list of some of the most common tube head styles you may come across:

- Flip-Top (most common tube head style)

- Brush

- Doe Foot

- Disc

- Dome

- Lotion Pump

- Needle Nose

- Pin Point

- Rollerball

- Slant Tip

- Soft Spatula

- Soft Tip

- Sponge Tip

Tubes are also versatile when it comes to decoration. As the final touch to stand out from the other products on the shelf, tubes can be decorated by a variety of methods. Decoration methods can range from labels, to in-mold decoration. Speak with one of our packaging specialists to see if tubes are a fit for your product and how Paramount Global can help! Contact us today!

Hayley is a marketing professional and copywriter with a background in crafting content for a diverse range of industries. She has been writing about packaging and supply chain logistics for Paramount Global since 2022. She specializes in explaining complex topics in a clear and engaging way and is an advocate for sustainability in packaging and supply chain management.

Read More

For over forty years, Paramount has been delivering perfectly integrated packaging and supply chain solutions.