NIR Plastic Sorting & Its Impact on Packaging

Recycling plastic is essential for sustainability because it allows us to recover non-renewable resources used to create plastic and reuse them while also effectively reducing our carbon footprint. However, plastic recycling has always been a challenge because different plastics need to be recycled in different ways. Some plastics are more recyclable than others. Different plastics have different molecular compositions that need to be grouped together before recycling and processing into post consumer resin (PCR). Cross-contamination jeopardizes the structural integrity of the PCR and can potentially leech unwanted chemicals from non-recyclable plastics, rendering the resin unusable. Chasing arrows with a number in the middle, often found on the bottom of containers, is a first step to identifying plastics, but many containers may not have a symbol.

The recycling infrastructure has traditionally struggled with accurately identifying different types of plastics due to the manual sorting process. However, with innovation, recycling, and the collective effort to work towards a circular economy, we can benefit from technology such as Near Infrared (NIR) spectroscopy which we will explore further below.

What is NIR plastic sorting?

NIR plastic sorting uses a near-infrared scanner to detect the wavelength signature of resins, for example separating PET from HDPE bottles. The scanner immensely improves accuracy and speed in the sorting process. It also helps detect contaminants that have entered the recycling stream.

How does NIR plastic sorting work?

NIR is a form of spectroscopy, operating at around 750nm and 2500nm which is near the infrared region. NIR spectroscopy can detect the specific molecular bonds in the plastic, and then automatically separate plastics by type. Studies have shown that with the right backlighting, NIR can also separate out bioplastics.

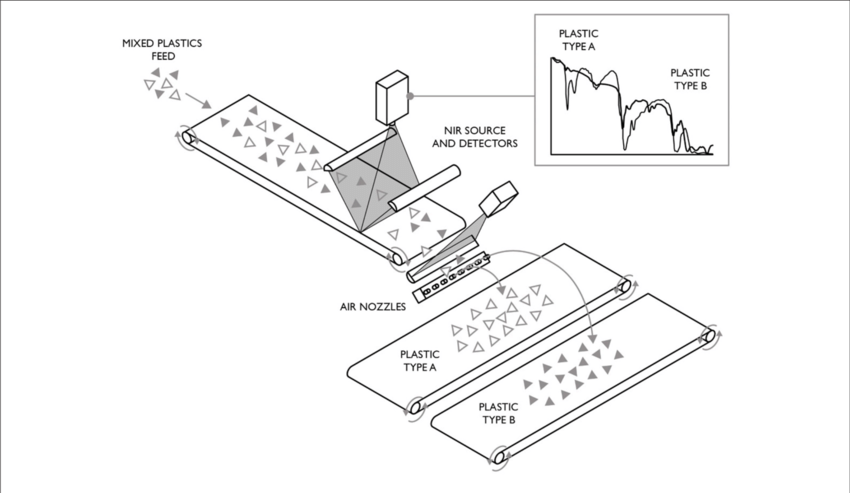

A conveyor belt transports a spread of mixed plastics under NIR optical sensors. Under the spectrometer, the different plastics are identified based on the spectrum of light reflected by the plastic. Compressed air will eject the target resins onto one conveyor belt, while the unidentified resin will fall onto another conveyor belt.

NIR plastic sorting is not the perfect solution and has some limitations. NIR sensors cannot separate plastic by color and have challenges identifying dark-colored plastic packaging due to pigmentation absorbing too much of the near-infrared beam. Shrink sleeve labels also deter NIR spectroscopy from accurately sorting because the plastic labels are often composed of a different plastic polymer, blocking the beam from identifying the container’s polymers.

However, NIR plastic sorting can be combined with other methods such as visual sensing and manual sorting to help increase accuracy and create an optimal recycling stream.

Impact of NIR Sorting on Recycling

A clean recycled material stream is vital for giving plastics a second life. NIR plastic sorting is a piece of a solution for plastics to be included when envisioning a sustainable future. Here are some of the ways NIR sorting improves recycling today.

Increased Recycling Rates

Automated sorting encourages recycling by requiring less separation of packaging materials by consumers or recycling workers. When consumers know that plastic can be effectively recycled, they are more likely to be proactive with recycling efforts. Building trust in the recycling system is just as important as using the system. Even fully educated consumers can make mistakes, and an effective sorting system is an extra layer of prevention for keeping plastic waste out of landfills to improve overall recycling rates.

Enhanced Sustainability

Improving recycling rates on its own already enhances sustainability, but an NIR plastic sorting machine saves time and energy by reducing the number of workers needed, and using less energy than other recycling methods, such as gravity sorting which has to be done multiple times.

Improved Product Quality

NIR sorting improves the accuracy of plastic separation dramatically. This reduces the number of contaminants, especially incorrectly sorted plastics.

By ensuring quality recycled resin is used for PCR packaging and showing how it is comparable to packaging made from virgin resin, consumer perception will shift to favoring PCR-packaged products. Improved sales of these products and increasing the ROl of recycling are benefits stemming from NIR sorting.

Reduced Contamination

Contamination is a major problem in our recycling system. Some contamination occurs at the consumer level, such as putting the wrong material into a recycling bin. Contamination can also occur later at the recycling facility where manual sorting by workers is susceptible to incorrectly sorted plastic types causing a contaminated recycling stream.

NIR technology can help reduce contamination during the sorting process. It can reduce instances where a batch of what is supposedly sorted PET plastic ready for processing turns out to be contaminated and unusable. NIR saves money and reduces the amount of plastic that ends up in landfills.

Cost Savings

As PCR continues to gain traction with consumers, cost savings will grow as more resources are invested in recycling technologies. NIR recycles faster by removing the labor-intensive process of sorting by hand and is done more accurately. As recycling infrastructure becomes more supported and high-quality PCR evolves into an abundant resource material, the cost of PCR can be driven down and make it a competitive option to virgin resin.

Increased Recycling Efficiency

Investing in NIR technology vastly streamlines the manual process of sorting with accuracy and speed. It can identify as many as twenty different plastics and sort them in a single run through the machine (while many other systems require multiple runs). This reduces the amount of time plastic is in the facility before being sent to its next destination for processing. Accuracy is also key to recycling efficiency since it prevents contamination and maximizes the amount of plastic recycled for reuse.

Optimizing Your Packaging Design for Better NIR Sorting

With NIR becoming the dominant method for sorting plastics, packaging designers have a responsibility to optimize their designs to work around NIR’s limitations. Packaging that can easily be sorted by NIR will be recycled more efficiently and successfully. Brands will continuously look for optimized packaging design geared towards sustainability as consumers demand more sustainable packaging and hold brands accountable for their impact.

Plastic Types

While NIR can handle most types of plastic, it currently struggles with bioplastics without additional equipment. Mixing bioplastics and regular plastic recycling will increase the risk of contamination. Even with these challenges, the industry continues to innovate to perfect the sorting process.

Colorants

The biggest limitation of NIR sorting is that it cannot sort dark-colored plastic, especially black plastic. The carbon pigments used to create black plastic absorb the infrared stream, blocking its sorting ability. Currently it is best to avoid black or very dark colored plastic that contains carbon pigments. If dark colored packaging is needed, consider using cardboard or paper labels to provide the dark color while keeping the plastic container light or transparent.

To address the challenge with dark pigments, another option is using NIR colorants which are designed and optimized to help NIR sort through dark colors. The pigments used are reflecting or transparent under infrared spectroscopy, and thus don’t interfere with the scanners. If dark plastic is key to your design, incorporating these pigments can also overcome this challenge.

Additives

Avoid using additives that can’t be recycled, but also avoid any additives that might interfere with NIR identifying the plastic’s “signature.” This includes additives that contain common polymer bonds that can cause misidentification and subsequent contamination.

An example of an additive that can affect NIR sorting is flame retardant additives which have been shown to respond in NIR, potentially affecting the separation. If additives are needed, make sure recycling facilities will accept your packaging and educate the consumer accordingly. Additives are typically more of a concern for e-waste and other long duration use plastics.

Layers and multi-material construction

Another major problem for NIR scanners is shrink sleeves. Shrink sleeves are made of plastic and often composed of a different polymer from the underlying package. The composition of the shrink sleeves are not easy for these machines to sort. Al is helping resolve this, but package designers should avoid printing or coloring sleeves black, and should also avoid large-area printing combined with high shrinkage. Basically, keep your shrink sleeves simple.

Multi-material construction is always going to cause an issue for mechanical sorting. Try to keep the area of each material large so they can more easily be separated. Layers that aren’t easily removable or separated should be avoided.

Labeling and printing

NIR sorting works best when there is minimal obstruction between the scanner and container’s material, but decoration is a key element to packaging, ranging from labeling to direct printing, that the scanners will need to overcome. To ensure NIR technology can successfully read the item that needs to be sorted, consider this end-of-life process during decoration design.

When decorating directly on the plastic container, avoid large areas of carbon black pigment. Labels cover less surface area than direct printing, but using paper labels can help minimize obstruction between the scanner and the container.

Ongoing Developments in NIR Sorting Technology

NIR sorting technology continues to improve, and the industry continues to innovate to address the challenges NIR technology faces today.

The use of machine learning to improve accuracy is also ongoing. Another thing being worked on is miniaturized spectrometers. These handheld units would allow hand sorters to quickly identify and sort polymers. This would allow plastic to be sorted by type at the manual sort phase when workers separate plastic from glass or paper.

They could also be used in smaller facilities where full-scale sorting would be expensive and unnecessary, such as municipal facilities in very small towns. This would reduce the contaminants being shipped from these towns to larger facilities. Ultimately, they could even be deployed at dumps to sort material as it comes in.

A Trusted Partner with Insight on Packaging Innovations

Working with a partner to be your packaging resource for new innovations can help your business flourish and stay ahead of competitors. At Paramount Global, we work closely with manufacturers and their technologies as they innovate through all levels of the packaging and supply chain. With 48 years of experience in the packaging industry, our expertise is what keeps our partners with us year after year as their businesses grow and prosper. By partnering with us, you gain access to a wealth of knowledge and information to ensure your packaging projects take advantage of innovations to meet your packaging goals. Contact us today to learn how we can be a partner to you.

Hayley is a marketing professional and copywriter with a background in crafting content for a diverse range of industries. She has been writing about packaging and supply chain logistics for Paramount Global since 2022. She specializes in explaining complex topics in a clear and engaging way and is an advocate for sustainability in packaging and supply chain management.

Read More

For over forty years, Paramount has been delivering perfectly integrated packaging and supply chain solutions.