KNOWLEDGE

Recycle Numbers: Is Your Package Recyclable?

Have you ever wondered what the numbers on the bottom of your plastic packaging mean? Does it mean that it’s a recyclable item? In this article, we’ll explore all you need to know about recycling numbers and codes while covering some important facts about rules and regulations regarding recycling.

What are recycle numbers?

Recycle numbers are a system for identifying different types of plastic and determining whether or not they are recyclable. The plastic recycling symbol containing the number is usually found on the bottom of plastic containers, inside a triangle of three arrows chasing each other. The chasing arrows symbol has become synonymous with identifying recyclables. However, just because there is a recycle symbol on your packaging doesn’t mean the packaging can be easily recycled curbside.

Understanding What Recycle Numbers Mean

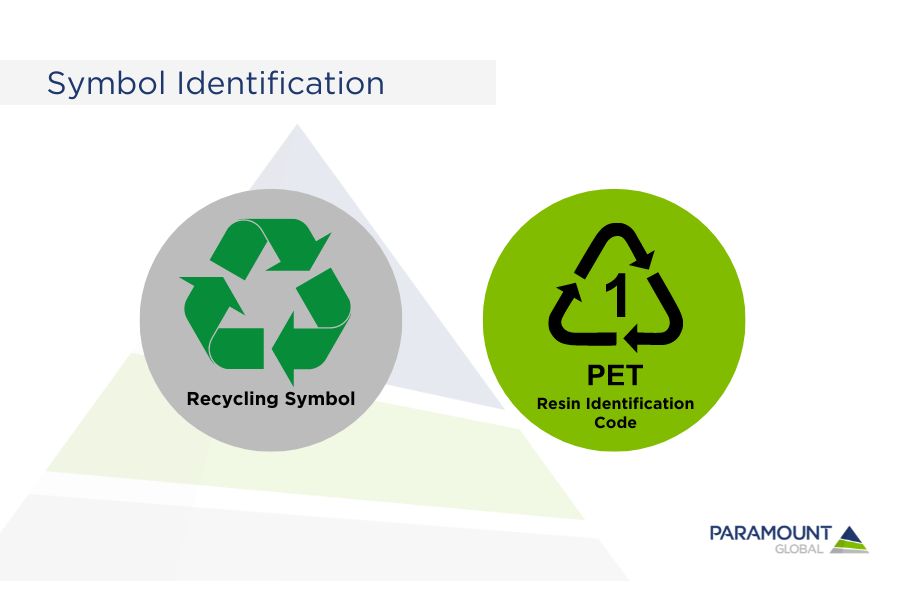

The rules and symbols for plastic products can cause confusion for consumers trying to figure out the meaning behind the symbols and how to recycle them. Not all plastic is recyclable, and there is a difference between Resin Identification Codes (RIC) and the Recycling Symbol found on plastic containers.

The Resin Identification Code (RIC) was developed by The Society of the Plastics Industry (SPI). The RIC consists of a number and code that identifies the resin type of plastic containers to help the public understand plastic types for recycling. The numbers and codes identify the type of plastic resin from which the packaging is made. There are seven unique resin identification codes, represented by a number from 1 to 7, enclosed in a triangle chasing arrows symbol commonly referred to as the recycling code.

However, the recycling code is solely the triangle with the three chasing arrows, which represent “Reduce, Reuse, Recycle.” This symbol was designed in 1970 by Gary Anderson, a student at the University of Southern California. His design was part of a nationwide contest sponsored by the Container Corporation of America (CCA) in response to World Earth Day. As consumers were becoming more environmentally conscious, the CCA wanted to develop a label for recycled and recyclable products and raise awareness about recycling.

These symbols are generally located on the base of the plastic container, accompanied by an abbreviation of the plastic resin type (PET or HDPE, for example).

Thirty-nine US states mandate the use of this coding system on plastic bottles and rigid plastic containers.

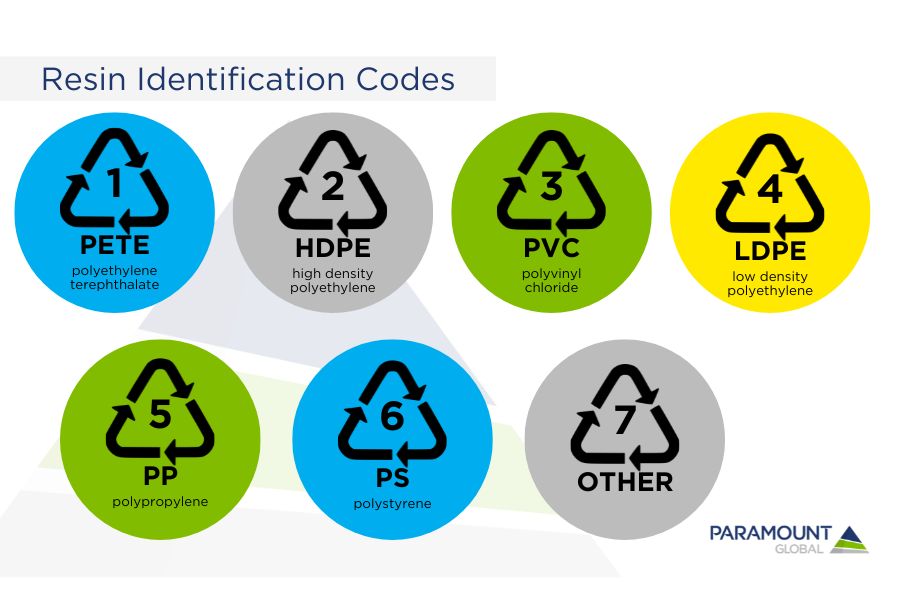

Plastic Numbers (1-7)

Also known as Resin Identification Codes:

1 – PET (Polyethylene Terephthalate)

PET or PETE is the easiest plastic to recycle and can be recycled curbside. Most commonly used for beverage bottles like soda or water, peanut butter, salad dressing, and vegetable oil containers. The post-consumer recycled (PCR) resin from this plastic is called rPET and can be recycled into fibers for carpets, fleece jackets, tote bags, food & beverage containers, and more.

2 – HDPE (High-Density Polyethylene)

HDPE is easy to recycle and can also be recycled curbside. Commonly used for dairy, juice, household cleaner, shampoo, and motor oil containers. The PCR material from HDPE is used for recycling bins, pens, floor tile, drainage pipes, plastic lumber, fencing, and more.

3 – PVC (Polyvinyl Chloride)

PVC is difficult to recycle because it has a lower melting point than PET and HDPE and is composed of chemicals that can contaminate our environment. It is commonly used for toys, wraps, vinyl siding, windows, plastic gloves, water-resistant clothing, and blister packs. When recycled, PVC can be turned into pipe, decking, gutters, carpet backing, mud flaps, traffic cones, and more.

4 – LDPE (Low-Density Polyethylene)

Depending on the form, LDPE is both easy and moderately difficult to recycle. The rigid form can be recycled curbside, but the flexible form (e.g., thin plastic bags used for bread and frozen foods, shrink wrap, bubble wrap, etc.) must be taken to store drop-off locations and cannot be put in the curbside recycling bin. LDPE is commonly used for container lids, squeezable bottles, shrink wrap, and bags. It can also be recycled into shipping envelopes; garbage can liners, floor tile, lumber, furniture, compost bins, and more.

5 – PP (Polypropylene)

PP is moderately difficult to recycle. Not all curbside recycling accepts PP, but the number of facilities accepting it is growing. The majority of plastic caps are made from PP and are often encouraged to be recycled with the container they close, even though the container may be made from another type of plastic. PP is commonly used for straws, yogurt containers, bottle caps, medicine bottles, condiment bottles, rope, furniture, luggage, and toys. The recycled PP material can be made into battery cases for cars, ice scrapers, oil funnels, storage bins, shipping pallets, brooms, brushes, cables, trays, and more.

6 – PS (Polystyrene)

PS is difficult to recycle. Polystyrene is often referred to as Styrofoam because of the similarities between Expanded polystyrene foam (EPS) and Styrofoam. However, Styrofoam is a trademarked brand manufactured by DuPont. This closed-cell extruded polystyrene foam (XPS) is different than EPS. Polystyrene can take various forms and can be made into rigid containers such as jars. The foam form is challenging to recycle due to its being composed mainly of air. Commonly used for disposable food service items, egg cartons, and protective packaging. When recycled, it can be turned into thermal insulation, thermometers, egg cartons, protective packaging, and more.

7 – Other

Plastics labeled as #7 or “other” are difficult to recycle due to their lack of standardized plastic identification. The symbol covers plastics such as BPA, other mixed plastics, and even new plastics designed to be more eco-friendly, such as PLA (polylactic acid). It is commonly used for three—and five-gallon water bottles, certain food containers, sunglasses, bulletproof materials, nylon, baby bottles, sports equipment, and more. Generally not recyclable, but if recycled, this material is turned into plastic lumber or used for other bottle applications.

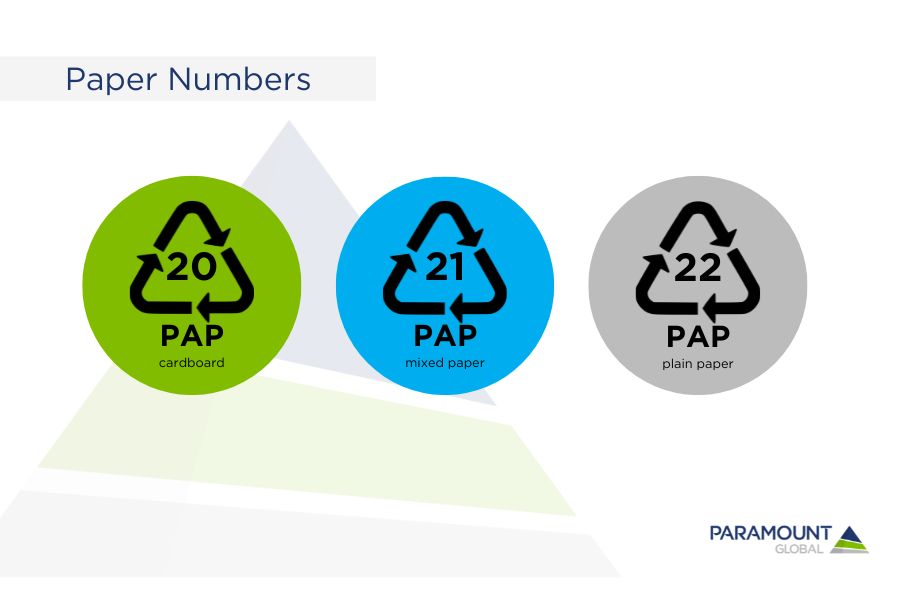

Paper Numbers

The majority of paper products are recyclable. According to the American Forest and Paper Association, In 2022, 67.9% of paper was recycled and 93.6% of cardboard boxes were recycled. However, laminated paper and paper that is dirty or greasy cannot be recycled. So that grease stained pizza box isn’t going to be recycled, toss it in the trash instead of the recycle bin. There are three types of paper recycling codes:

20-PAP

Recycle code 20-PAP is used for corrugated cardboard and corrugated fiberboard, one of the most widely used materials for shipping and retail packaging.

21-PAP

Recycle code 21-PAP is used for non-corrugated fiberboard, paperboard, and mixed paper. This type of material is commonly used for packaging food items such as cereal boxes and cracker boxes. This material is also commonly used for gift boxes.

22-PAP

Recycle code 22-PAP is used for plain paper, such as letter or printer paper, books, newspapers, and catalogs. This material is also used in packaging applications, such as bags and straws, which use paper-based materials.

Metal Numbers

There is a wide variety of metal products and packaging used in our everyday lives. One of the most common products is aluminum beverage cans, which are widely recycled. They’re one of the easiest and most profitable products to recycle. However, other metal items may be more challenging to recycle. You’ll want to check to see what is accepted locally. There are two types of recyclable metal codes:

40 Fe: Steel

Recycling code 40 FE refers primarily to steel food and aerosol cans, not steel used in buildings or ships. Steel is a sustainable material that can be infinitely recycled and reused, requiring fewer resources and energy than creating new steel from raw materials.

41 Alu: Aluminum

Recycling code 41 Alu refers to aluminum packaging, including soft drink and beverage cans, aluminum foil, single-use food containers, and more.

Glass Numbers

A majority of the most common glass products, such as jars and bottles, can be easily recycled or, better yet, reused. However, there are specific types of glass or items that will present more of a challenge to recycle. For example, electronics that contain glass may be recyclable through an electronic waste program, or you can check to see what’s accepted locally. Certain items like broken stemware, drink glasses, porcelain, windows, ovenware, and Pyrex cannot be recycled. These glass types are composed of mixed materials, which can contaminate the recycling process for bottles and jars. Other items, such as broken or burned-out light bulbs, may need to be disposed of as household hazardous waste. Check your local guidelines to learn how to dispose of the type of bulb properly. One of the great things about glass containers is that they can be reused indefinitely for various things, like storage containers or even planters. There are a number of ways to reuse glass containers, so save money by reusing items you already have on hand! Here are some of the most frequently used glass recycling codes:

70 GL: Mixed Glass

Recycle code 70 is used for mixed glass containers or multi-part containers. Check with your local facility for how to recycle this type.

71 GL: Clear Glass

Recycle code 71 is used for clear glass containers. These jars often hold food items like sauces, preserves, personal care products, and household items. Clear glass is easily recyclable, but be sure to thoroughly rinse the item out so that it actually gets recycled. Depending on your local regulations, some cities will require you to separate your clear glass from your colored glass, while some facilities will do the sorting for you.

72 GL: Green Glass

Recycle code 72 is used for green glass, such as wine bottles and olive oil bottles. Green glass is good for products that are sensitive to light.

Recycling is, unfortunately, a complicated process that varies greatly depending on where you live. As consumers, we are inclined to recycle packaging that looks to be recyclable, but what really happens once that item enters the recycling stream? There are a number of factors that stand in the way of recyclability. Let’s take a look at some of the most common issues when it comes to recycling.

Complicated Symbols and Inconsistent Rules

Recycling is a complex issue that confuses most people due to inconsistent rules that vary by city, state, and country. On top of that, messaging to consumers about recycling is limited. This lack of education has led to most people just tossing any and all “recyclable materials” into the recycling bin, which leads to more waste going to landfills instead of being recycled.

Multi-Material Packaging

Multi-material packaging is not recyclable unless the materials are separated. For example, a plastic pump with a metal spring cannot be recycled unless the spring is separated from the rest of the pump. Recent packaging innovations, such as mono-material products like all-plastic pumps make it easier to recycle these products.

Contamination Issues

Dirty items tossed in the recycling bin will not be recycled due to the damage that contamination can cause to the recycling process. If recycling is important to you, then you want to be sure that the items you are recycling are free of food and other contaminants that will harm the recycling process and result in sending more waste into the environment.

Consumer Confusion and Education

Considering the different rules and regulations based on location, it’s not surprising that there’s so much confusion around packaging recyclability. The best way to clear up confusion is to research how to recycle in your local area. Recycling rules and regulations in Europe are more advanced than in the United States. For example, in the UK, the on-pack recycling labels do a great job of educating consumers on how to recycle products. If there were universal global implementation of on-pack recycling labels, that would be one way to educate the public in a significant way on how to properly recycle products.

Does a recycling symbol guarantee recyclability?

A recycling symbol on its own without a resin code attached is usually found on a recyclable item or a recycling bin. However, if the recycling symbol encloses a resin identification code, then it is not a guarantee that the item is recyclable, and you’ll have to do a little work to figure out if the item can be recycled. For example, if it’s a code holding the number 7 inside, you know from the chart above that resin identification code #7 is not easily recyclable. It doesn’t mean that it can’t be. Still, you’ll have to figure out for yourself what the material consists of, and if it’s not curbside recyclable, do you need to take it to a composting facility or another place to dispose of it in an environmentally responsible way?

Local Municipality Regulations and the Reality of Recyclability

Recycling, while universally recognized as a key component of environmental responsibility, is a complex and difficult practice due to varying local municipality regulations. These regulations directly impact the recyclability of materials, and influence both businesses and consumer behavior. Understanding the regional variations in recycling programs, evolving rules and material restrictions, operational impacts of policy changes, and the relationship between consumer expectations and brand reputation is essential for navigating this challenging landscape.

Regional Variations in Recycling Programs

Factors like local policies, infrastructure capacities, and community priorities influence the inconsistency in recycling programs across municipalities. Some regions have extensive recycling programs that accept various plastics, while others may have limited options due to the availability of recycling facilities or market demand for recycled materials. This variation in recycling programs poses challenges for residents and businesses, as they need to stay informed about local regulations and adapt their recycling practices accordingly to ensure compliance and optimize their efforts.

Evolving Rules and Material Restrictions

As technology advances and market demands shift, recycling rules and material restrictions also evolve. New materials and packaging innovations often outpace regulatory adjustments and recycling technology development, leading to confusion about what is truly recyclable. Additionally, contamination concerns—where non-recyclable materials are mistakenly placed in recycling bins—can lead to stricter material restrictions. For instance, some municipalities have responded to high contamination rates by reducing the types of plastics accepted in recycling programs. Staying abreast of these evolving rules is necessary for both businesses and consumers to contribute effectively to recycling efforts.

Operational Impact of Policy Changes

Changes in local recycling regulations can significantly impact businesses, especially those in the manufacturing, retail, and waste management sectors. Companies may need to alter their packaging materials to comply with new recycling guidelines, potentially incurring higher costs or facing supply chain challenges. Waste management companies, on the other hand, must adapt their sorting and processing capabilities to align with changing material acceptance criteria. These operational adjustments require careful planning and communication to minimize disruptions and ensure a smooth transition.

Consumer Expectations and Brand Reputation

Consumer awareness and demand for sustainable practices have never been higher, placing pressure on brands to demonstrate environmental responsibility. Recycling plays a key role in this equation, with consumers increasingly expecting brands to use recyclable materials and to actively participate in reducing waste. Failure to meet these expectations can negatively impact a brand’s reputation and customer loyalty. Alternatively, companies that effectively navigate the complexities of recycling regulations and communicate their efforts transparently can improve their brand image and attract environmentally conscious consumers.

Growing Importance of Green Packaging Alternatives

Green packaging alternatives will continue to grow in importance for as long as sustainability is a top priority. Today, waste management and recycling infrastructures are collapsing all around us, yet halting the production of new materials would have equally devastating consequences. Working to improve the infrastructure of these systems is the best way forward. Though plastic has been vilified as a packaging material, rPET is considered a sustainable material for a variety of reasons. Investing in green packaging alternatives that minimize our carbon footprint and generate products that are easily compostable or biodegradable are steps toward creating a more circular economy.

Partnering with Sustainable Packaging Suppliers

A great way to ensure sustainability throughout your supply chain is to partner with packaging suppliers whose sustainability values are measurable and align with yours. That way, you can feel confident knowing that your partners are doing their part to reduce waste, lower their carbon footprint, and manage their supply chains in the most environmentally responsible way.

Make More Informed Sustainability Choices for Your Company Today

With sustainability becoming an ever-present priority for business owners and suppliers alike, it’s important to make sure that you’re on course to comply with new rules and regulations before they take effect.

At Paramount Global, we make it our responsibility to know how to best support our customers as they work toward compliance with upcoming laws and legislation. From advising on sustainable material types to providing guidelines for getting your business up to date, we are here to help. Our professional team of packaging specialists can support your business growth with our tailored services, like sourcing, packaging design, warehousing, and supply chain management.

Contact us today to see how we can be a partner to you!

This article was originally published on March 12, 2019 and updated on April 4, 2024.

Hayley is a marketing professional and copywriter with a background in crafting content for a diverse range of industries. She has been writing about packaging and supply chain logistics for Paramount Global since 2022. She specializes in explaining complex topics in a clear and engaging way and is an advocate for sustainability in packaging and supply chain management.

Read More

For over forty years, Paramount has been delivering perfectly integrated packaging and supply chain solutions.