KNOWLEDGE

Understanding the Total Cost of Ownership in Packaging

When you run a business that ships items and uses packaging, you need to find an affordable way to pay for that packaging. While outsourcing packaging is one option, some companies look to buy their own packaging materials, machines, and software to handle their packaging in-house. As you weigh the pros and cons of various packaging options, you must calculate the costs of the various options available to you. One tool to use as you do this is to perform a total cost of ownership analysis to consider all the costs, including both direct and indirect costs, of your packaging and packaging processes.

What is Total Cost of Ownership (TCO) in Packaging?

The purchase price of your packaging is not the only cost associated with handling your packaging needs in-house. The total cost of ownership is the total cost of acquisition, maintenance, operation, repair, use of packaging along with the machines and materials needed to use it. Calculating the TCO is actually quite complex and requires careful analysis of how you use your packaging and the long-term investment required to package and ship an item.

Key Elements of TCO in Packaging

To calculate your TCO for packaging, you must consider several costs and then compare them to the expected value of the equipment or materials. These costs include:

Acquisition Costs

Acquisition costs are relatively simple to calculate. These are the costs of purchasing the packaging materials, hardware, software, machines, and equipment. Many companies stop their calculations here, assuming they have the full cost of their packaging. However, while the initial purchase price is important, the actual cost takes more items into account, including the indirect costs of a product.

Operational Costs

Operational costs play a significant role in a product packaging operation. These indirect costs encompass various aspects, such as managing packaging equipment, payroll expenses, and handling products post-packaging and before shipping to customers.

One of the biggest operational costs is equipment operation. Packaging machines require energy, labor, and regular maintenance. This includes electricity costs, maintenance expenses, wages for machine operators, and repair costs. In cases where vehicles are used in packaging operations, the total cost of ownership of the vehicle must be factored into operational costs, considering fuel, maintenance, and insurance.

In addition, you may need to pay for upgrades or more supplies for your packaging equipment. For example, if the label printer runs out of paper or ink, you have to buy more. If you change the design of your bottle to match your new marketing scheme, you may need to upgrade the packaging equipment to accommodate the new design. Software upgrades can also add potential costs to your shipping operations. All of these operational costs must be included in your TCO.

Equipment machinery is just one part of your operational costs. You also will want to consider the cost of loading and unloading your items. If packaging is not done in an efficient way that is easy for your team to handle, you can have significant labor costs associated with the loading and unloading of your packaged items. This must be part of your TCO.

It’s important to note that the costs of operation have many variables to consider and will be unique to each company. A comprehensive understanding of these costs is essential to effectively manage your budget and business operations.

Disposal Costs

As packaging equipment approaches the end of its life cycle, its value and functionality inevitably decline. When that happens, you will need to responsibly dispose of it. Disposal costs are an intrinsic part of the long-term expenses associated with packaging and should be factored into your TCO analysis.

For certain types of packaging, you will also need to consider the disposal cost of the packaging itself. Regulatory organizations have established guidelines that dictate how and where you can dispose of specific packaging materials. Compliance with these packaging regulations can potentially impact your disposal costs, especially if the onus of disposal falls upon you.

Why TCO Matters in Packaging

Why does figuring your TCO matter in the world of packaging? The best way to manage your costs of operation is to know what they are. When you can identify your long-term costs, you can decide if you want to lower those costs in-house or by finding a third-party packaging partner that can assist you in saving money.

Businesses often ignore the importance of packaging, despite its significant impact on labor and maintenance time. However, packaging plays a critical role in operations, as it directly affects the ability to package and ship items, which is essential for generating revenue. Finding ways to reduce packaging costs without compromising efficiency is crucial for running a successful and profitable operation. TCO is something decision-makers should calculate because it’s a valuable tool in optimizing packaging expenses.

Why Should You Consider TCO?

Understanding the TCO for packaging solutions is essential because it is not a fixed cost. With the right knowledge, businesses can lower total cost of ownership figures, leading to significant cost savings and improved operational efficiency. By considering factors beyond the initial price of packaging, organizations can make informed decisions that contribute to their overall health and success.

Improved cost control and budgeting

To create an effective budget, it is important to have a comprehensive understanding of your expenses. Conducting a TCO analysis for your packaging can help you achieve this. By performing this analysis, you can proactively budget for the long-term costs associated with your packaging, reducing the likelihood of unexpected expenses. Regaining control of your packaging budget is a key advantage of this calculation.

More informed comparisons between packaging options

Keeping the long-term price of your packaging at the forefront of your mind will help you when comparing pricing. While the initial purchase price may be tempting, factoring in long-term costs can reveal a different picture when making a purchasing decision. For example, a bottling or labeling machine with a low upfront price might seem appealing. However, a TCO analysis may show a low expected lifespan or high maintenance costs, resulting in the item’s short-term price being offset by the high overall cost of ownership and shorter useful life.

Optimized packaging for efficiency and cost reduction

Conducting a TCO analysis on your packaging can identify areas where you are not utilizing your equipment well or where you can increase efficiency to lower costs. Direct cost analysis alone may overlook areas where long-term savings come in. It is necessary to consider the long-term costs to find places to save.

Reduced risk of hidden costs impacting profitability

Performing a TCO analysis for your packaging process can uncover potential hidden extra costs that might be driving down your bottom line. These hidden costs, such as the costs of labor in your packaging and shipping operations or the costs of maintenance of your packaging equipment, impact your overall profitability. While it is not always possible to eliminate these costs completely, identifying them through a TCO analysis allows you to develop strategic plans to mitigate their impact on your business.

Calculating TCO for Packaging

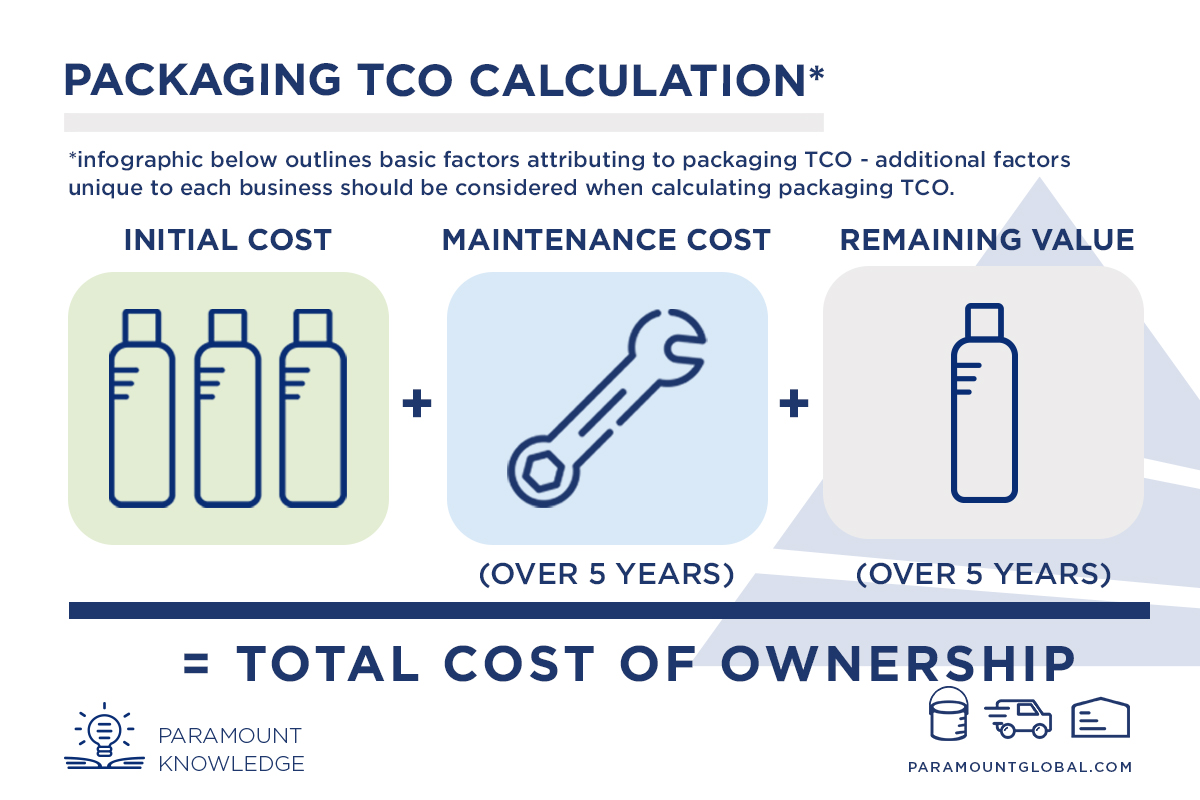

Every business is unique, and the formula for calculating TCO for your packaging operations can be complicated, especially because some parts of the packaging process are consumable. Still, the basic factors to consider are the initial cost, maintenance costs over five years, and the remaining value of the item after five years. Start with the initial cost, then add the maintenance costs. From this, subtract the remaining value after depreciation. This will show you the total cost of ownership.

TCO Across Different Packaging Materials

Packaging materials have their own unique TCO factors to consider. Here are some common materials and the factors that impact their TCO.

Labeling

Labeling is an important part of the packaging process, and the cost of ownership of labeling equipment and materials includes many parts. First, you must cover the initial equipment and software purchase to make the labels, including the purchase of label paper. Then, you must consider the cost of maintaining that equipment and the labor associated with printing and sticking labels. Finally, the disposal of extra labeling material is an additional factor to consider.

Boxes and Bottles

The containers you store your products in are part of your packaging materials. There is the initial cost for the raw materials, then the cost to form those materials into your desired packaging shape, fill the box or bottle, seal it, and ship it. All of this requires specialized equipment and labor, which adds to the TCO.

Packaging Machines

When calculating the TCO of packaging machines, you must consider the initial purchase price and expected lifespan of the machine. Next, consider the operating costs. With equipment like this, the maintenance costs and potential downtime, including the costs of that downtime to your organization’s profitability, are also factors to consider.

Making Informed Packaging Decisions with TCO

TCO analysis will help you choose the most cost-effective packaging solution, either within your organization or with the help of outside parties. As you make decisions about your packaging, don’t forget to consider other parts of the packaging process. For example, you may find that more costly packaging provides better product protection for your items or that a particular design costs a little more but helps protect your brand identity. While cash flow and budgeting are both important factors to consider, use TCO as part of your overall planning and keep these other factors in mind as well.

It’s Time to Consider TCO When Making Packaging Decisions

You make packaging decisions on a regular basis, but you may not consider the additional costs and long-term expenses of packaging. While TCO is not the only factor to consider, it can help you make the best decisions about your packaging. As you look to better understand your packaging costs and find ways to save on them, Paramount Global and our team of packaging experts are here to help. Contact us today to learn how we can be a partner to you and help optimize your business solutions and budget!

Hayley is a marketing professional and copywriter with a background in crafting content for a diverse range of industries. She has been writing about packaging and supply chain logistics for Paramount Global since 2022. She specializes in explaining complex topics in a clear and engaging way and is an advocate for sustainability in packaging and supply chain management.

Read More

For over forty years, Paramount has been delivering perfectly integrated packaging and supply chain solutions.