UN Rating Codes: Everything You Need to Know

There are always risks associated with shipping products and materials. However, some materials are hazardous to humans and the environment if mishandled or spilled. Packaging plays a vital role in ensuring dangerous materials are properly stored to be safely transported. With a range of materials with different levels of hazards, a rating system known as UN ratings is used to identify the packaging that is compatible with the hazardous material. In this article, we’ll further explore everything you need to know when it comes to packaging hazardous goods with UN rated packaging.

What are UN rating codes?

The UN rating code is a set of standards developed by the United Nations and required for shipping and storing hazardous materials.

The UN rating code can be found on the outer box of various types of packaging, including boxes, bottles, pails, and drums. A UN rating code includes the UN logo consisting of a lowercase ‘u’ stacked above a lowercase ‘n’ enclosed with a circle, followed by a six code series of numbers and letters that is found on packaging. The packaging should be permanently embossed with the UN rating code on the bottom and either the side or the top of the outer packaging. These codes serve as identifiers for packaging that has undergone thorough testing to meet specific standards. The inclusion of ‘UN’ in the code signifies that the standards are established by the United Nations and enforced by the U.S. Department of Transportation (D.O.T.).

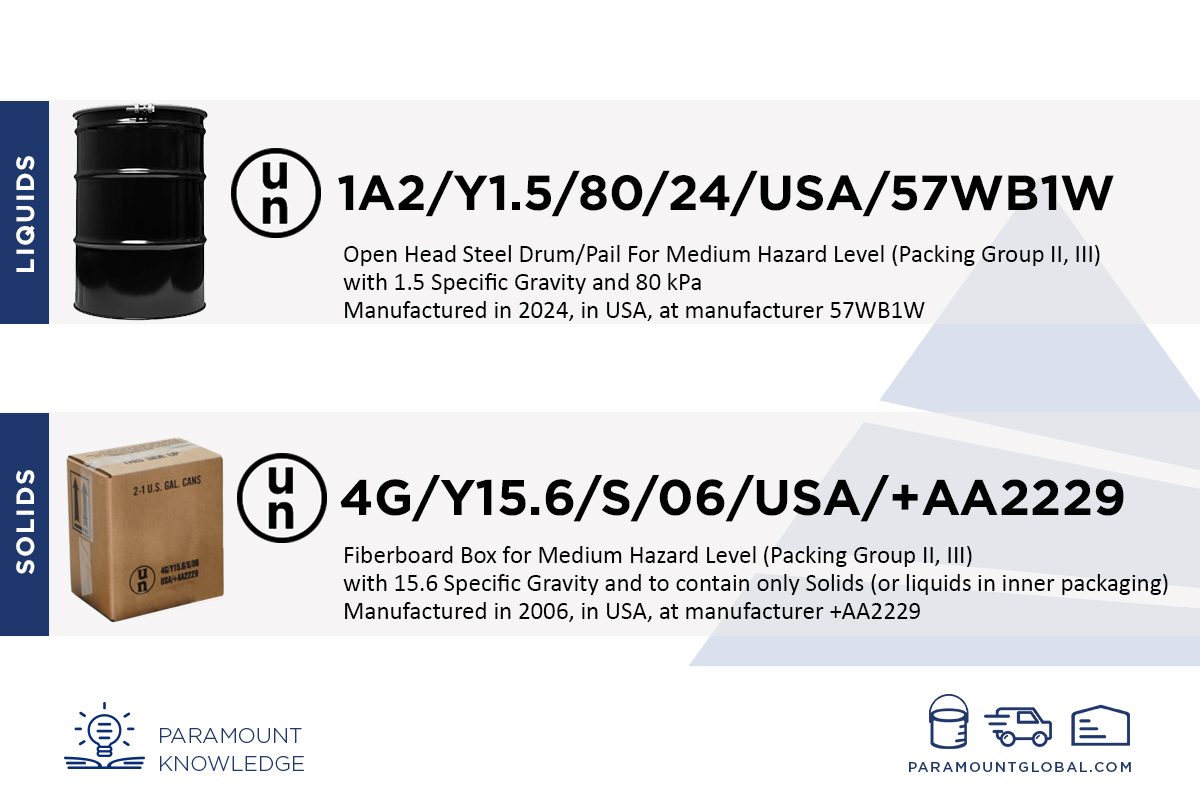

How to read UN rating codes

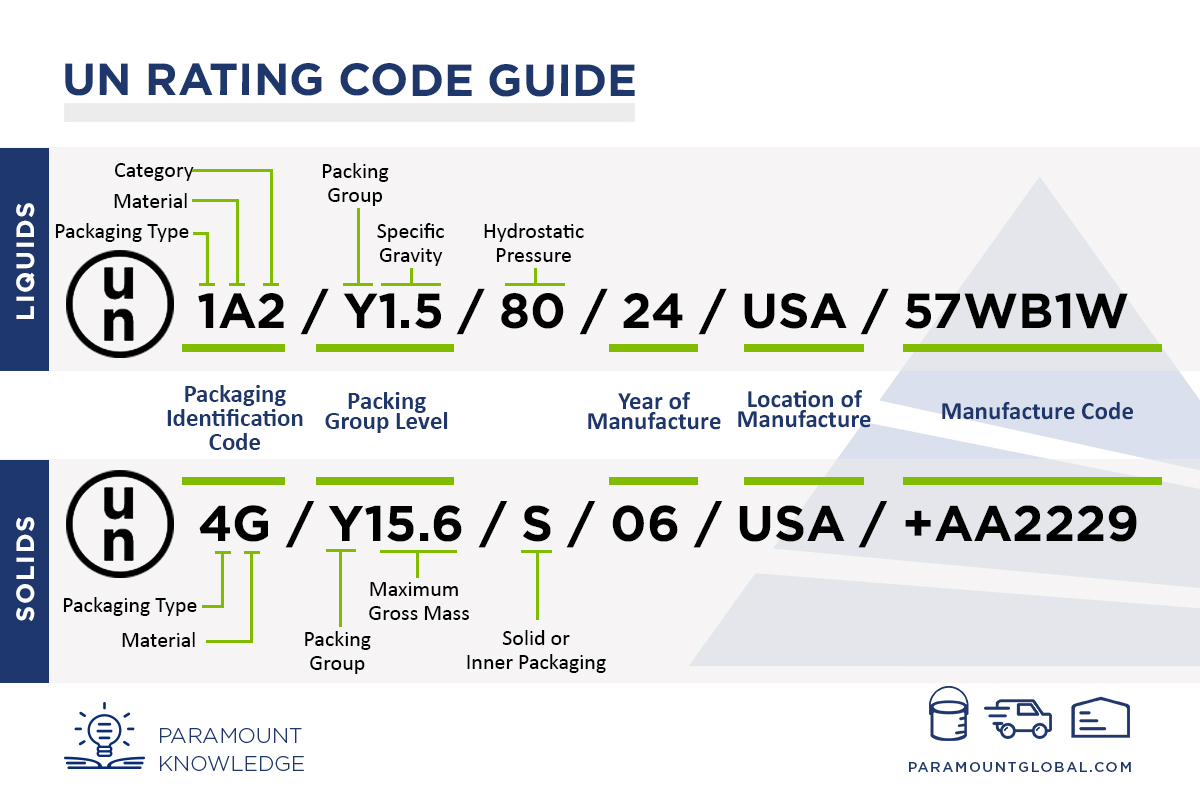

A UN rating consists of a series of numbers and letters divided into six sections broken up by a slash. These sections offer detailed information about the material compatibility with the packaging and include details about the manufacturing of the packaging itself:

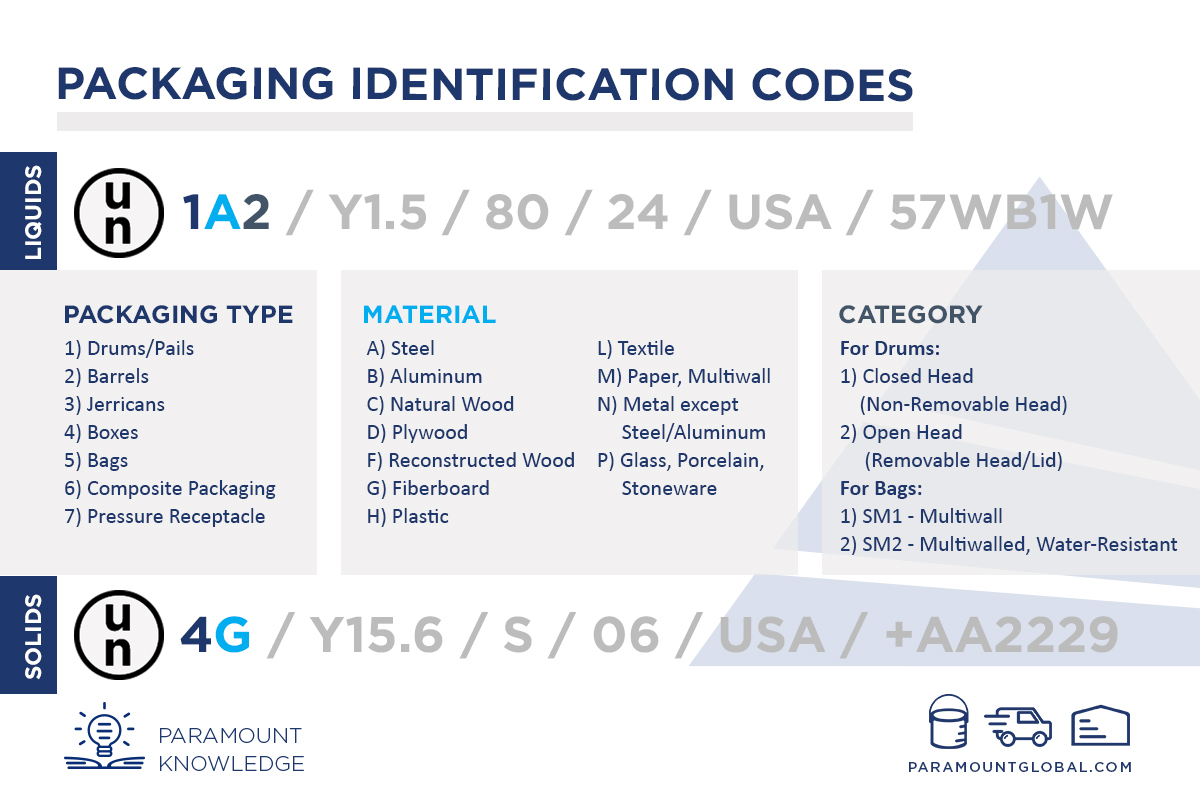

Packaging Identification Code

The Packaging Identification Code System identifies the type of container. It contains three characters, with each character representing the following:

Container Type

- 1 – Drums/Pails

- 2 – Barrels

- 3 – Jerricans

- 4 – Boxes

- 5 – Bags

- 6 – Composite Packaging

- 7 – Package Receptacle

Container Material

- A – Steel

- B – Aluminum

- C – Natural Wood

- D – Plywood

- F – Reconstructed Wood

- G – Fiberboard

- H – Plastic

- L – Textile

- M – Paper

- N – Any metal other than steel or aluminum

- P – Glass, porcelain, stoneware

Container Category

- ( 1 ) Closed Head (one mold piece)

- ( 2 ) Open Head (removable lid)

UN rating codes apply to a complete packaging solution, which can include the closure, container, and even the box that contains the closure/container.

A common code is a UN 1A1 rating for packaging liquid hazardous materials or a UN 1A2 rating for packaging solid hazardous materials. The first character in 1A1 or 1A2 represents the type of container (in this case, it’s 1 because we’re talking about a drum). The letter ‘A’ represents the type of material that the container is made out of (in this case, it’s steel). The third character, the letter 1 or 2 represents the head type:

- 1 – Closed head or no removable top

- 2 – Open head

Packing Group Level Equivalent:

The Packing Group Level Equivalent identifies the Hazard Level and Specific Gravity for liquids, or Maximum Gross Mass (kg) for solids. This section features the letters X, Y, or Z, indicating the varying levels of danger associated with the hazardous chemical within the packaging.

- X: Packaging Group I (highest level of danger)

- Y: Packaging Group II (medium level of danger)

- Z: Packaging Group III (lowest level of danger)

Packaging that has undergone testing and approval for containing hazardous materials can also safely contain substances that pose a lower degree of danger. For example, a package that is suitable for storing extremely hazardous explosives can also accommodate a mild household chemical. However, a package that has only been tested and approved for a household chemical will never safely contain an extremely hazardous explosive.

Consider this guideline:

- X can contain packing groups I, II and III

- Y can contain packaging groups II and III

- Z can contain only packaging group III

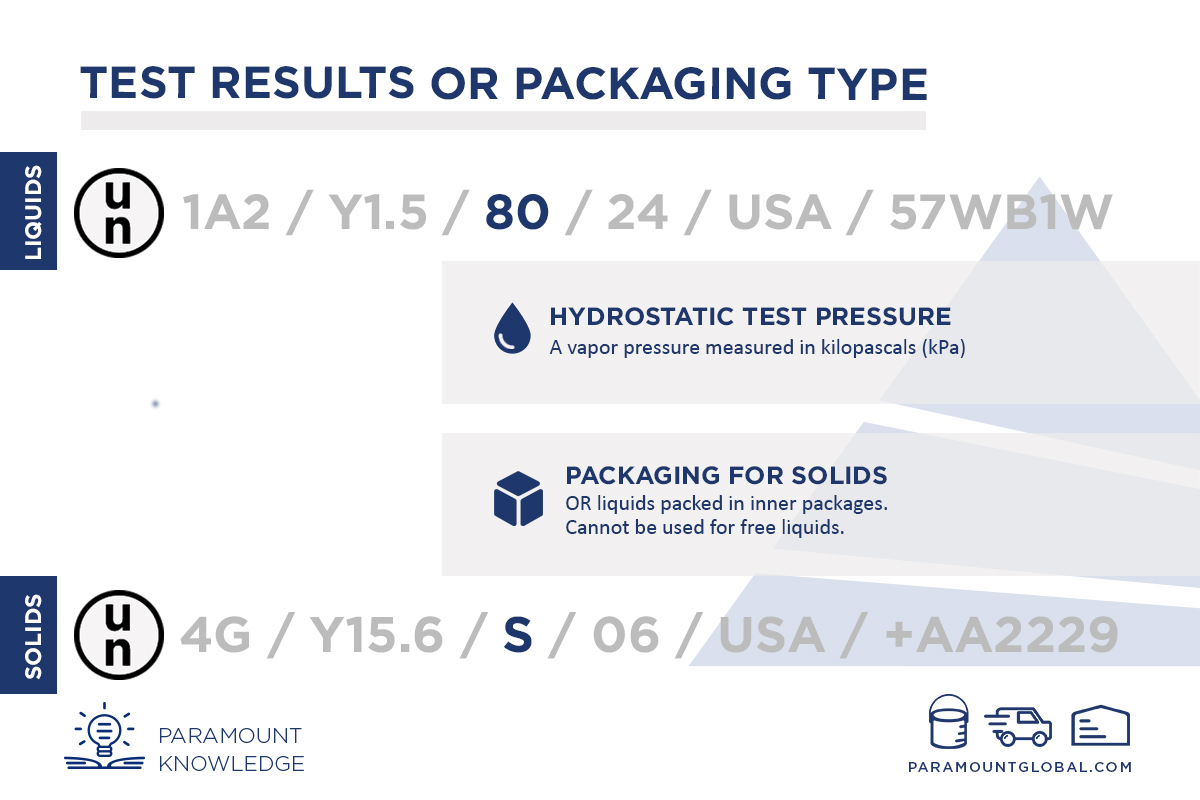

Test Results or Packaging Type

In this section, the code will vary based on whether the packaging is for liquids or solids. For liquids, the section will identify the test results of a Hydrostatic Pressure Test which measures the vapor pressure in kilopascals (kPa).

For solids, the section will note a ‘S’ to identify the packaging is designed for solids (which can also include inner packaging that contains liquids). No free liquids can be contained in a ‘S’ rated package.

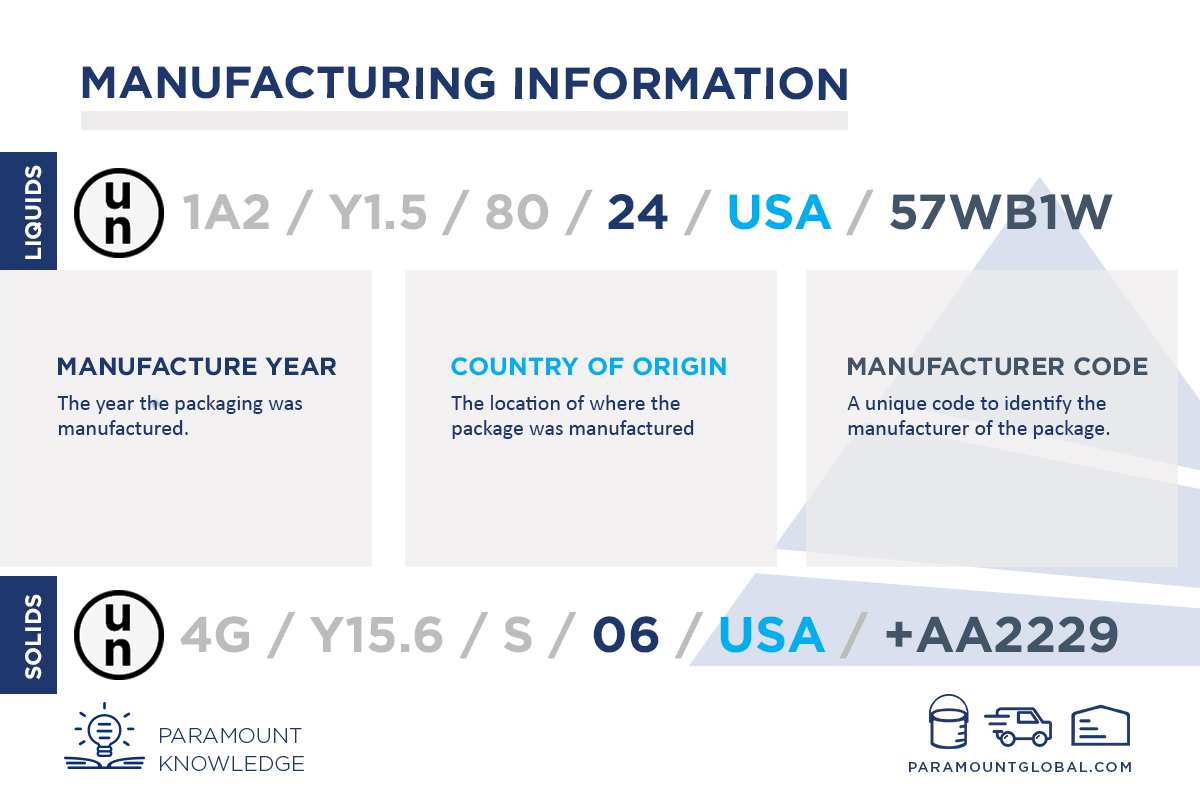

Manufacturing Information

The Manufacturing information is divided into three sections:

-

Year of Manufacture: This section identifies the year the packaging was manufactured.

-

Country of Origin: This section refers to the location where the packaging was manufactured.

-

Manufacturer Code: The manufacturer code identifies the UN certified agency or manufacturer of the container.

Why are UN rating codes important?

As an internationally accepted standard, regulations for shipping hazardous materials are streamlined to be recognized across industries and countries. UN ratings are designed to identify the right packaging for different hazardous materials. The more hazardous the materials, the higher the risk it is to the environment it travels through. Using the correct UN rated package for these types of materials is vital to prevent potentially disastrous spills. From solids to liquids, UN rated packaging will have a unique code that identifies exactly what type of material the packaging solution is designed for and information on the manufacturing of the packaging for traceability.

How is a rating calculated for hazardous materials?

In order to obtain UN packaging certification, rigorous tests are conducted to verify the package’s integrity in various environments and situations. These tests include:

Hydrostatic Pressure Test

The Hydrostatic Pressure Test ensures that packaging can endure pressure changes during air transport. Compressed air is used to simulate these changes, and the packaging must withstand the pressure without leaking for at least five minutes.

Leak Proof Test

The Leak Proof Test ensures the package will not leak when internal pressure is applied. The package is filled up to overflow capacity, and internal pressure is applied to make sure that the container does not leak.

Drop Test

The Drop Test is used to evaluate the integrity of packaging when dropped from a specific height with the center of gravity over an impact point. It ensures that the packaging can withstand impact and maintain its integrity. Different types of packaging (such as corrugated boxes) may require additional testing at various positions to guarantee their durability.

Stack Compression Test

The Stack Compression Test examines the structural integrity of the package when stacked. It involves stacking the packaging for 28 days at or above 104 degrees Fahrenheit.

Vibration Test

The Vibration Test evaluates the structural integrity of packaging in bumpy settings. It involves placing the package on a vibrating platform and shaking it until a 1/16-inch plate can slide underneath. During the test, the package may bounce, rotate, and move. Afterward, it is inspected for leaks or other potential test-induced damages.

By passing these tests, UN-rated packaging guarantees the safe transportation of hazardous materials and adheres to strict quality and safety standards.

UN Packaging Codes and Their Meanings

As noted in the above Packaging Identification Code section, a series of numbers and letters identifies a variety of features of a UN Package.

You may see any one of three different letter-number combinations to indicate the packaging identification code:

- Three-part (packaging type + material + subcategory): For example, 1A1 means a non-removable head steel drum.

- Number + letter (packaging type + material): For example, 4D for plywood box

- Two numbers + two letters ( in the order of number-letter-letter-number). The first number will always be a 6, meaning the packaging is composite. The two letters represent the inner and outer package materials, and the second number represents the type of packaging. For example, 6HA1 is a composite package with plastic inside and steel outside of a drum.

Are UN-rated packaging materials required for all hazardous shipments?

Using the correct packaging of dangerous goods is vital for public safety. Using the wrong packaging can lead to serious consequences, including injury to transportation workers, environmental harm, and catastrophic damage to transportation vessels.

The Packaging Group Level Equivalent can be used as a guide to determine the most appropriate packaging for a product. This involves selecting the most suitable hazard classification, as well as considering the physical attributes of the product.

There are many items that are considered dangerous goods (such as lithium batteries or battery-powered devices, aerosols, and oxygen cylinders) or flammable liquids (such as perfumery products or alcoholic beverages). The Hazardous Materials Table offers a comprehensive guide to the appropriate packaging sections, specific quantity limitations, and special provisions or exceptions associated with hazardous materials.

How can I find the UN Rating of a product or service?

The following steps should be taken when looking for the UN rating of a product or service:

- Review Product Documentation

- Consult Safety Data Sheets (SDS)

- Contact the Manufacturer or Supplier

- Check Regulatory Resources

- Use Online Resources

- Consult with Experts

What factors might influence a UN Rating change over time?

A UN rating for hazmat packaging is valid for five years, but the validity of UN test reports varies by country. While some countries, such as Belgium, Netherlands, and Germany, consider the reports to have unlimited validity, others, like France and England, set a validity period of five years.

A UN test report has unlimited validity if these three conditions are met:

- The product undergoes annual inspection.

- There are no alterations to the product.

- No legislative changes affect the product.

If any of these conditions are not met, the product must be retested.

What happens if you ship a hazardous material without the proper packaging?

Shipping hazardous materials requires specific regulations set by organizations like IMDG, DOT, and IATA. Proper packaging, labeling, and documentation are crucial for everyone’s safety. The shipment must display the classification, UN number, consignee and consignor’s names and addresses. For example, lithium batteries, being highly flammable, require special packaging with cushioning. Failure to comply with these regulations can result in hefty fines, up to $75,000 dollars.

Work with an Expert to Ensure You’re Always Compliant and Informed

The transportation of hazardous materials carries many risks. Make a plan well ahead of time about how you’re going to transport your hazardous materials. Working with reliable suppliers who can navigate the complexities of transporting hazardous goods through the supply chain will save you a lot of time and frustration.

Paramount Global is a full-service packaging distributor and supply chain solution. We are here to help you optimize your business. Contact us today and learn how we can be a partner to you!

Hayley is a marketing professional and copywriter with a background in crafting content for a diverse range of industries. She has been writing about packaging and supply chain logistics for Paramount Global since 2022. She specializes in explaining complex topics in a clear and engaging way and is an advocate for sustainability in packaging and supply chain management.

For over forty years, Paramount has been delivering perfectly integrated packaging and supply chain solutions.