KNOWLEDGE

What is Extended Producer Responsibility (EPR)?

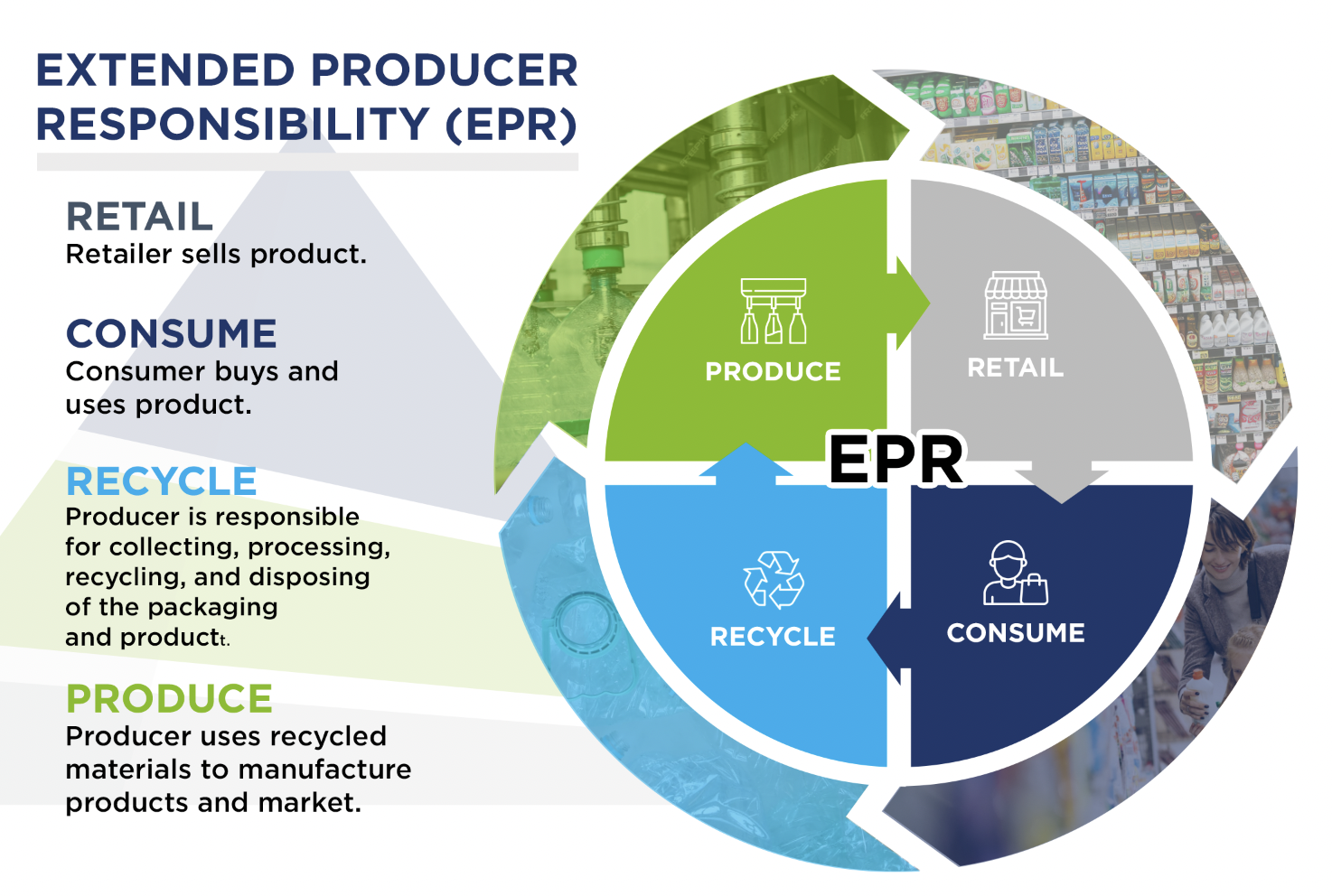

In today’s evolving regulatory landscape, businesses face increasing pressure to take accountability for the full lifecycle of their products. Extended Producer Responsibility, or EPR, is a policy approach that shifts the burden of waste management from consumers and municipalities to manufacturers and suppliers, driving them to design, produce, and dispose of products more sustainably.

EPR programs are rapidly shaping industries worldwide, impacting packaging choices, recycling systems, and corporate sustainability strategies. For businesses, understanding and complying with EPR regulations is a competitive necessity.

From reducing environmental impact to avoiding hefty fines, companies that embrace EPR can gain a strategic advantage while contributing to a circular economy.

In this article, we’ll break down the fundamentals of EPR, its growing influence across global markets, and what businesses can do to stay ahead.

Understanding EPR: A Shift in Accountability

Extended Producer Responsibility (EPR) makes manufacturers financially and operationally responsible for the end-of-life management of their products. By shifting the burden of waste disposal to producers, EPR incentivizes companies to design products with sustainability in mind, ultimately reducing environmental impact and supporting circular economy principles.

Origins and Purpose of EPR

The concept of EPR emerged in the late 20th century as a response to growing concerns about waste management and resource depletion. Sweden and Germany were among the first countries to introduce EPR policies in the 1990s, targeting packaging waste and electronics. Since then, EPR programs have expanded globally, covering industries such as plastics, textiles, batteries, and automotive components.

At its core, EPR is designed to:

- Reduce waste by promoting product durability, reusability, and recyclability.

- Increase recycling rates through producer-funded systems.

- Relieve taxpayers of disposal costs by making manufacturers financially responsible.

- Drive innovation in materials and take-back systems

How EPR Works in Practice

Under EPR regulations, companies are typically required to:

- Register with relevant programs.

- Pay fees based on product type and recyclability.

- Implement proper waste collection and recycling methods.

- Report compliance data to authorities.

As EPR legislation evolves and expands globally, businesses that adapt to these regulations will be better positioned for long-term success.

How EPR Shifts Responsibility to Producers

Before EPR regulations, waste management relied heavily on taxpayer-funded municipal systems. As waste volumes grew and recycling systems became overwhelmed, EPR policies were introduced to shift the financial and operational burden to producers. Today, EPR regulations require companies to:

- Fund waste collection and recycling instead of relying on public services.

- Design products and packaging for sustainability and recyclability.

- Implement take-back and disposal programs through PROs or internal systems.

- Meet government-mandated recycling and recovery targets.

The Environmental Benefits of Extended Producer Responsibility

EPR is a powerful tool for reducing environmental impact by ensuring that companies take responsibility for the entire lifecycle of their products. By incentivizing sustainable design, efficient recycling, and waste reduction, EPR helps drive the shift toward a circular economy.

EPR Regulations: What You Need to Know

EPR policies vary widely across industries and regions, but they all share the same goal—shifting the responsibility of end-of-life product management from consumers and governments to producers. Understanding these regulations is crucial for businesses looking to ensure compliance and maintain a competitive edge.

EPR Regulations in the U.S. vs. the World

EPR regulations are evolving worldwide, but their implementation and enforcement vary greatly by region. While many European and Asian countries have long-established EPR frameworks, the U.S. has taken a more fragmented approach, with regulations differing at the state level rather than being standardized nationwide.

States such as California, Maine, Oregon, and Colorado have enacted packaging EPR laws, while others focus on specific industries like electronics, batteries, and mattresses.

This approach creates challenges for businesses that must navigate multiple, sometimes conflicting, state regulations.

Key challenges in the US include:

- Lack of federal oversight, leading to inconsistencies across states.

- Varied reporting requirements make compliance complex for nationwide businesses.

- Different fee structures based on state-specific waste management goals.

How EPR Regulations Impact Businesses

As EPR regulations become more widespread, businesses must adapt to new compliance requirements that affect operations, financial planning, and product design. Companies that fail to meet these obligations risk fines, legal challenges, and reputational damage. However, those that proactively align with EPR policies can unlock opportunities for cost savings, sustainability leadership, and consumer trust.

What Products Are Covered, and Who Is Responsible Under EPR?

One of the biggest challenges in complying with EPR laws and regulations is understanding what products are regulated and who qualifies as a producer. These definitions can vary significantly by region, making it imperative that businesses know their obligations within the supply chain.

What Products are Covered?

EPR programs apply to a wide range of products that contribute to waste streams. Current laws focus heavily on:

- Paper products: magazines, catalogs, and office paper

- Plastics: single-use utensils, plastic-coated packaging, and food service items

- Packaging materials: protective bags, cardboard boxes, and bubble wrap, CPG packaging

Who is Considered a Producer?

While definitions differ by jurisdiction, the term “producer” includes:

- Brand owners

- Importers and distributors

- Packaging manufacturers

- Retailers selling under private labels

Some states focus on upstream producers, such as brand licensees and manufacturers, while others target brand owners and public-facing companies. To ensure compliance, companies must identify their role in the supply chain and understand the specific EPR requirements that apply to them.

Certain states provide exemptions based on annual revenue, product sales volume, or location. This allows small businesses or low-volume producers to be exempt or face reduced fees, easing compliance for emerging companies.

Which Industries Are Most Impacted by EPR?

EPR regulations heavily impact industries that produce high volumes of waste or hard-to-recycle materials. Key sectors include packaging, electronics, batteries, textiles, and pharmaceuticals, as these products contribute significantly to landfill waste and pollution. Companies in these industries must meet stricter compliance requirements, including product take-back programs, material recovery targets, and recycling contributions.

How to Stay Compliant with EPR Regulations

To meet EPR requirements, businesses should identify applicable regulations, register with producer responsibility organizations (PROs), and implement take-back or recycling programs.

Using sustainable packaging, tracking waste management data, and submitting compliance reports to regulatory bodies helps avoid fines and maintain brand reputation.

Partnering with EPR experts and staying updated on evolving laws ensures long-term compliance and operational efficiency.

Why U.S. Brands Should Pay Attention to Europe’s Packaging Regulations

In 2024, the European Parliament passed the Directive on Empowering Consumers for the Green Transition (ECGT), a law designed to fight greenwashing and help consumers make informed, sustainable choices.

The directive bans vague and misleading environmental claims, such as “eco,” “green,” or “climate neutral,” unless they are backed by verified evidence and certified by trusted labels like the EU Ecolabel. The law mandates that any green certification is verified by an independent third party to ensure credibility.

This regulation addresses a critical issue in the EU, where over 50% of green claims are misleading or unverified. The European Environmental Bureau (EEB) praised the directive as a vital step toward reducing corporate greenwashing and improving transparency and trust in product marketing.

David Feber, senior partner at McKinsey & Company and global packaging leader, warns that packaging regulations are becoming increasingly stringent and complex, directly impacting the materials that manufacturers can use. He advises U.S. companies to look to European regulations as a preview of what’s coming, and what to prepare for.

Looking ahead to 2030, the EU is proposing several major packaging regulations:

- Recycled Content Requirements: Plastics must include 10% to 35% post-consumer recycled content, based on product type.

- Limits on Compostable Plastics: Restricted to those with clear environmental benefits.

- Standardized Recycling and Labeling: All member states must implement uniform recycling systems, with packaging labels reflecting the changes.

- Reusable Packaging Targets: 10% to 20% of sold containers must be reusable for designated end-use applications.

- Mandatory Deposit Return Systems: All member states must establish deposit return programs for beverage containers by January 1, 2029.

A recent McKinsey survey shows that while 75% of companies have made sustainable packaging commitments, many still lack the tools, infrastructure, and strategies to meet them.

As regulations tighten and consumer expectations rise, brands are rethinking materials, marketing claims, and packaging technologies to stay compliant and competitive.

Understand Your EPR Obligations

EPR requirements vary by industry, location, and product type. Therefore, it is essential for businesses to assess their specific responsibilities. Regulations may mandate producer registration, recycling contributions, and take-back programs based on material usage and waste impact.

Staying informed about regional laws and industry-specific guidelines ensures full compliance and prevents costly penalties.

Implement Sustainable Product and Packaging Strategies

Designing products with recyclability, reusability, and minimal waste in mind is key to meeting EPR standards. Businesses can reduce compliance costs by using eco-friendly materials, optimizing packaging, and eliminating unnecessary components. Sustainable design not only aligns with regulations but also enhances brand reputation and customer loyalty.

Track and Report Compliance Data Accurately

Accurate data tracking is essential for demonstrating EPR compliance and avoiding fines. Businesses must monitor material usage, recycling rates, and waste management efforts, then report this data to regulatory bodies. Implementing digital tracking systems or working with compliance partners streamlines reporting and ensures transparency.

Partner with Compliance Experts and Take Advantage of EPR Programs

Navigating EPR regulations is complex, but partnering with industry experts and third-party compliance services can help simplify the process. Producer Responsibility Organizations (PROs) and government-supported EPR programs offer guidance, collection services, and cost-sharing solutions. Leveraging these resources can help businesses stay compliant while focusing on sustainability and growth.

How Paramount Global Can Help You Navigate EPR Compliance

EPR is more than just a regulatory requirement—it’s a transformative shift toward a more sustainable, circular economy. Businesses that proactively embrace EPR can reduce costs, strengthen brand reputation, and stay ahead of evolving regulations.

At Paramount Global, we support EPR compliance with sustainable packaging solutions designed to meet industry standards while minimizing environmental impact through our commitment to sustainability.

Contact us today to learn more, or browse our catalog to explore our wide array of packaging solutions!

Hayley is a marketing professional and copywriter with a background in crafting content for a diverse range of industries. She has been writing about packaging and supply chain logistics for Paramount Global since 2022. She specializes in explaining complex topics in a clear and engaging way and is an advocate for sustainability in packaging and supply chain management.

Read More

For over forty years, Paramount has been delivering perfectly integrated packaging and supply chain solutions.