KNOWLEDGE

Your Guide to Wholesale Packaging Bottles

In the world of packaging, bottles play a major role in protecting and delivering a wide range of products, especially liquids. With new bottle designs popping up on store shelves daily, it’s intriguing to see what features can make or break bottle packaging.

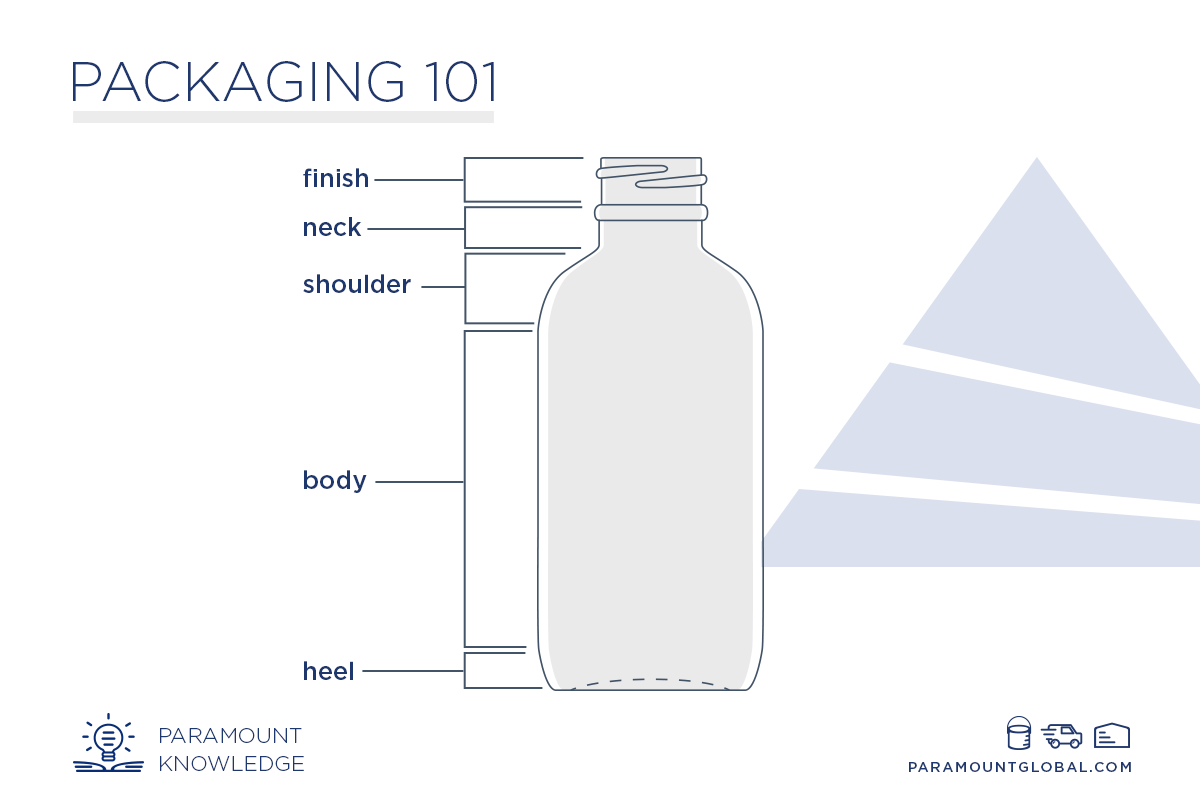

The Anatomy of a Packaging Bottle

Let’s take a closer look at the anatomy of a packaging bottle and discover the different styles, shapes, and materials that make each bottle unique. Different types of bottles have unique traits and are tailor-made to suit specific needs and industries. However, at their foundation they include five main features: finish, neck, shoulder, body, and heel.

There are some exceptions to the standard anatomy of a bottle, such as the cubitainer and bottles with a unique custom design. The features of a bottle will also vary in height, width and capacity size depending on the type of packaging, whether it’s a stock package or custom packaging. Over time, certain bottle shapes have become a popular option for stock packaging in specific industries and can be identified by the following names.

12 Common Packaging Bottle Shapes

1. Boston Round

The Boston Round bottle’s distinctive features include rounded shoulders, a narrow neck for easy pouring, and a wide body. Boston Rounds are commonly used with liquids and other low to medium viscous products, such as essential oils, tinctures, beverages, personal care, edible oils, lab supplies, automotive, and other applications.

Boston Round glass bottles are a popular choice for beverages like kombucha and cold brew. The glass packaging is available in a few colors, common choices are clear or flint, cobalt blue, and amber glass bottles. Amber is the most commonly used color due to its dark tint to help protect products sensitive to light such as kombucha. Green glass bottles are available in the market, but they’re a less common color.

Boston Round plastic bottles are a popular choice for personal care and household product packaging. Plastic bottles are commonly found in clear and white colors, but they can also be customized as needed.

2. Bullet Round

The Bullet Round bottle’s distinctive features include rounded shoulders, a narrow neck for easy pouring, and a slim body. Also referred to as a ‘Cosmo Round’ or an ‘Imperial Round’, this style is mainly found in plastic containers. The diamond round bottle also closely resembles this style.

Bullet round bottles are typically used for liquid products ranging from beverages to shampoos. They are also used for personal care, cosmetics, pet care, beverages, and other applications. Common colors for Bullet Round bottles include clear/flint, natural, and white.

3. Cubitainers

The Cubitainer is a sustainable rigid packaging solution that offers several benefits. Cubitainers consist of a collapsible inner bag housed within a corrugated cardboard box. The distinctive characteristic of a Cubitainer is its flexibility, which allows it to be collapsed into a ‘knocked down’ version to save space or fully assembled into a box. The lining within the cubitainer helps to extend the shelf life and preserve the product.

The Cubitainer’s space-saving design, flexibility, cost-effectiveness, ease of use, and durability make it a popular choice for holding and transporting liquid products. Their lightweight, collapsible, and stackable design reduces transportation and storage costs, making them a cost-effective alternative. From an environmental perspective, the bladder of the Cubitainer is made of a mono-material, and the outer corrugated box makes them both easily recyclable.

Cubitainers are commonly used for beverages, lab supplies, chemicals, pharmaceutical products, and other applications.

4. Cylinder Round

Cylinder Round Bottles offer several benefits and capabilities, making them a versatile and practical packaging solution in various industries. The defining features of a Cylinder Round include sharp shoulders, a narrow neck for easy pouring, and a slim body.

One key advantage of Cylinder bottles is their structural strength. The cylindrical shape provides excellent resistance to internal pressure and external forces, optimizing space efficiency.

Customization options include various sizes and materials catering to specific product needs. Cylinder Round Bottles can also include features like child-resistant closures and custom decorations, ensuring product safety and brand recognition.

They are widely used in pharmaceuticals, beverages, personal care, cosmetics, chemicals, and other industries.

5. Carafe

The Carafe Bottle is distinctive for its long, narrow, ridged neck and wide, round body. The ridges on the neck of the bottle can be uniquely identified as a ‘beehive’ carafe bottle and are designed to provide a better grip for the consumer. Other types of carafe bottles with different neck designs provide a variety of ergonomic grip options.

The Carafe Bottle is most commonly made from high-density polyethylene (HDPE) and is typically used for industrial chemicals, household cleaning products, automotive chemicals, and agricultural products. It’s a popular option for many products that require spraying as a dispensing option.

6. Dairy Square

The Dairy Square Bottle is an opaque high-density polyethylene (HDPE) plastic square jug. The opaque square shape provides a barrier from direct sunlight, which is especially important for dairy products and other beverages that have nutrients that can quickly deteriorate if not protected. The larger sizes, commonly referred to as jugs, have a handle at the top, near the opening, making them ideal for pouring and carrying. The smaller bottles, ideal for single servings, are known as DBJ (Dairy Beverage & Juice) bottles.

Although they’re called dairy squares or milk jugs, the sturdy design of these containers is commonly used for packaging bulk liquid food products such as dairy products, fruit juices, and water. However, the 1/2 gallon jug is also great for industrial solutions such as cleaning, gardening, and automotive chemicals.

7. Juice/Beverage

There are several different styles of bottles that are used for dairy beverage and juice containers (DBJ). The first thing to identify when deciding on what style of bottle would be the best option for your product, is what are the most common bottles used in the market for your specific type of product. It’s important to select a type of packaging that signals to consumers what type of product is inside. For instance, a gallon of milk in anything other than a milk jug might seem like an odd choice to consumers, even if the rationale behind it was to stand out and be unique.

While taking risks is part of running a business, industry-specific packaging types exist for a reason. There are plenty of ways to customize a stock bottle option so that it stands out on the shelf and highlights your unique brand identity. Here’s a list of juice and beverage bottles that are favored today:

- DBJ Decanter: These clear polyethylene terephthalate (PET) plastic bottles are popular for dairy beverages and fruit juices.

- DBJ Square: These versatile clear square PET bottles are available in various sizes and styles. They can be smooth or include a label panel and are commonly used for juices, smoothies, protein drinks, dairy beverages, and more.

- DBJ Juice: These clear PET bottles have a rounded shoulder and cylindrical or square body. They are commonly used for juices, teas, coffees, sports drinks, and water.

- DBJ Pinch Grip: Pinch Grip Juice Bottles have a ribbed, wide body and are made of PET plastic. Their unique body shape allows for better handling and control when pouring. Commonly used for juices, teas, edible oils, smoothies, sports drinks, and more.

- Woozy: The glass Woozy Bottle has a long, narrow neck that tapers in towards its opening. It is a popular type of glass sauce bottle used for hot sauces.

8. Dropper

Dropper Bottles are recognized for their small bottle size ranging from 5ml to 30ml. Their small capacity and specifically the 18mm neck finish are distinctive features of the dropper bottle and are ideal for holding highly concentrated products. These bottles can be customized with various dispensing droppers for administering a controlled amount of liquid. The dropper mechanism consists of an insert or pipette in the bottle lid.

Droppers are commonly used for essential oils, lab supplies, e-liquids, flavors and fragrances, aromatherapy, and other applications.

9. F-Style

Plastic F-style bottles are heavy-duty containers with a rectangular body shape and an ergonomic handle at the top for easy control when dispensing and carrying the product. Their rectangular shape also provides for convenient shipping and storage. Most F-style bottles are made from HDPE for chemical resistance. These bottles are available in a range of sizes and neck finishes.

Plastic F-styles are commonly used for industrial solvents, like cleaning, gardening, and automotive chemicals.

10. Industrial Round

Industrial Round bottles are cylindrical jugs designed for handling bulk liquids and food items. The round shoulders, thin handle, and wide body are distinct features of the Industrial Round. Bottle sizes typically range from 32 oz to 128 oz to accommodate a variety of products in various industries. The built-in handle enables easy carrying, and the narrow neck allows for precise pouring of liquid products.

Made of durable HDPE, this sturdy bottle provides a cost-effective packaging option for industrial chemicals, household cleaning products, automotive products, and food products such as condiments, flavorings, sauces, and more.

11. Modern Round

The Modern Round bottle, also known as a hydrogen peroxide bottle, is recognizable by its sloping shoulder, deep label panel, and rounded base. The indented surface of the label panel helps protect the label from abrasion.

Made of durable HDPE plastic, the Modern Round is chemically compatible. It is most commonly used for liquid products in pharmaceuticals, personal care, chemicals like solvents and acids, and other applications.

12. Packer

Packer bottles, also known as pill bottles or vitamin bottles, are commonly used in the pharmaceutical and nutraceutical industries. They have rounded shoulders and a wide neck for easy filling and dispensing. Packer bottles are measured in cubic centimeters (cc), which are equivalent to milliliters. For instance, a 500cc bottle is equivalent to a 500ml bottle.

Packer bottles are made of HDPE, PET, glass, or metal and come in a range of sizes and colors depending on product needs. Plastic Packer bottles are commonly found in clear, amber, dark amber, and white, while glass Packer bottles are frequently used in clear, amber, and cobalt blue. Aluminum Packer bottles are also increasing in popularity for their recyclability. These bottles are generally used for pharmaceuticals, vitamins, nutritional supplements, gummies, and more.

The bottles listed here only scratch the surface of available styles. You can even design your own bottle with custom packaging if you prefer a style totally unique or if your product doesn’t fit within the standard stock sizing.

In addition to bottles, you will want to complete your package with suitable caps or closures. Closures come in various shapes and styles, from a dispensing cap with a pump or sprayer to a continuous thread screw-on cap for packaging for a complete, secure solution.

Selecting the Right Bottle for Your Product

Selecting the right bottle for your product can be a daunting task. Here are a few key points to keep in mind as you go through the process:

- Material: Choose between glass, plastic, or metal based on product type, durability, and environmental impact.

- Size and Shape: Ensure it fits your product’s volume and is easy for consumers to handle and store.

- Compatibility: Confirm the bottle material is compatible with your product to avoid chemical reactions or spoilage.

- Closure Type: Select a cap or lid that ensures a proper seal and ease of use.

- Design and Branding: Consider a design that reflects your brand identity and attracts your target market.

- Regulatory Compliance: Ensure the bottle meets industry regulations and safety standards.

- Cost and Availability: Balance between quality and budget and ensure consistent supply.

- Sustainability: Opt for recyclable or biodegradable options to appeal to eco-conscious consumers and comply with growing sustainability regulations.

Considering Regulatory Considerations and Compliance

When packaging a new product, it’s important to verify that you are meeting all packaging regulations. Here are some things to consider as you’re developing your packaging strategy:

Material Safety

- Safety standards: Bottle packaging must adhere to stringent safety standards to guarantee that it does not pose any health risks.

- Food contact materials: Materials intended to come into contact with food must be approved for safety and meet specific regulatory guidelines.

- Hazardous materials: Many containers holding hazardous materials require UN certification. Ensure that your packaging meets any necessary UN ratings.

Labeling Requirements

- Mandatory information: Labels on bottles must include essential information such as product name, ingredients, manufacturer details, and expiration dates.

- Clear and accurate labeling: Labels must be clear, legible, and accurate to prevent misleading consumers and ensure compliance with regulations.

Sustainability and Recycling

- Recyclability symbols and instructions: Bottles should feature resin codes and recyclability symbols. It would be beneficial to go a step further and provide a label guide for consumers on properly disposing of or reusing the container when empty.

- Recycled content requirements: Regulations mandating a certain percentage of recycled content in bottle packaging to promote environmental sustainability are becoming increasingly popular worldwide. Incorporating post-consumer recycled plastic into your packaging strategy will help ensure you’ll be prepared for this regulation when it takes effect.

Specific Regulations by Region

- International standards: Different regions may have their own standards and regulations that packaging must comply with, such as the EU’s REACH or the FDA regulations in the US.

- Compliance resources: Companies can access various compliance resources, such as regulatory databases and consulting services, to ensure their packaging meets all relevant regional regulations.

Staying ahead of packaging rules and regulations will help you build a long-term packaging strategy. If you’re selling internationally, you’ll also want to be sure that you are meeting the requirements of the territories where you are distributing your product.

Emerging Trends and Innovations in Packaging Bottle Design

The most innovative products hitting the market today are centered around sustainability. In today’s climate, sustainability should be top of mind when building your packaging strategy. Not only because regulations are popping up across the globe, but for the health and safety of our planet. From the amount of waste that enters our oceans and waterways to the lack of infrastructure around recycling, it will take a collective responsibility to reduce waste. As consumers and legislation demand brands to contribute towards a sustainable future, innovations such as bioplastics and other biodegradable or compostable materials are growing offerings from the packaging industry to meet these demands. Keep your finger on the pulse of design trends and packaging innovations to stay ahead of the curve and adapt your packaging strategies accordingly.

Choose the Best Bottle Packaging for Your Product

When choosing the best bottle packaging for your product, you want to make sure you select a packaging solution that not only meets your needs but helps your product shine amongst the competition.

At Paramount Global, we have been helping businesses like yours choose the best packaging and supply chain solutions for 48 years and counting. Our dedicated team of packaging experts are standing by to help you take your packaging to the next level. Contact us today to discover how we can be a full-service partner to you!

This article was updated on May 22, 2024

Hayley is a marketing professional and copywriter with a background in crafting content for a diverse range of industries. She has been writing about packaging and supply chain logistics for Paramount Global since 2022. She specializes in explaining complex topics in a clear and engaging way and is an advocate for sustainability in packaging and supply chain management.

Read More

For over forty years, Paramount has been delivering perfectly integrated packaging and supply chain solutions.