KNOWLEDGE

Guide to Bottle Neck Finishes, Thread Sizes, & Dimensions

It’s essential to have a clear understanding of bottle neck finishes, thread sizes, and dimensions when considering packaging for your product. When it comes to the process of selecting a closure for your bottle or another container, there are several measurements needed to ensure a secure and sealed fit. In this guide, we will cover the key points you need to know to understand bottle neck finishes.

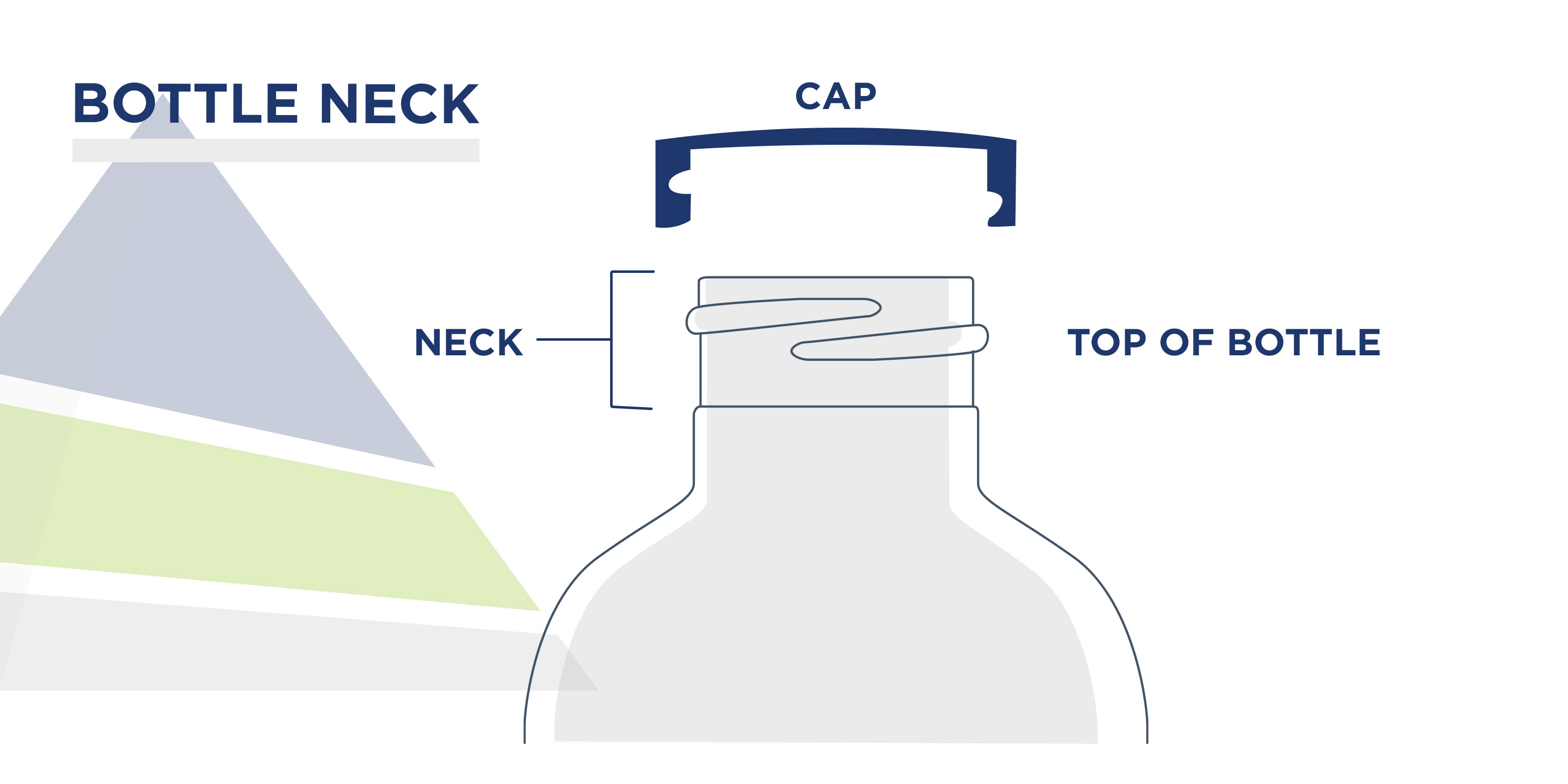

What is a bottle neck?

A bottle neck refers to the narrowest part of the bottle. Bottles feature a smaller mouth (opening) than the diameter of the body. Bottle designs naturally taper in to accommodate the smaller opening which creates the ‘neck’ section of the bottle. The narrow neck of a bottle provides more control when handling product and also allows the use of a wide variety of closures (or caps) and dispensers.

What is a bottle neck finish?

The neck finish on a bottle refers to where the outer threads on a bottle, or other type of container, connect to the cap or closure to hold the lid in place. The term neck finish is more commonly used with bottle containers since the word ‘neck’ is interpreted as the narrow section leading to a small opening. When referring to wide-mouth containers and jars, the term “thread finish” is more commonly used. Ultimately both ‘thread finish’ and ‘neck finish’ refer to the same part of a container: where the closure meets and seals the container.

The length and number of threads determine how a container will be sealed. The most common type of closure used with bottles is continuous threads which utilize a twisting motion.

Manufacturers include the neck width and thread style as part of their product specifications. These neck finishes are usually represented by:

- A two-digit number (the neck width)

- A three-digit number (the thread finish)

The neck finish numbers are separated by a dash, hyphen, or forward slash, such as 38-400 or 38/400. However, it can also be identified as a single number like 38mm.

The first number is always presented in mm and refers to the outer diameter of the threads. The second number represents the thread finish. For example, if a bottle features a 38-400 neck finish:

- 38 represents the “T” dimension or neck width which is the measurement across the neck opening including the threading in millimeters.

- 400 indicates one thread turn around the container’s neck which is the thread finish.

To find a matching cap and container, the cap size must have the same width and thread style for it to be a mate, meaning a 38-400 neck finish will only be compatible with 38-400 caps. The following sections will outline how to identify neck finishes and highlight common finishes found in the packaging industry.

How to Measure a Neck Finish

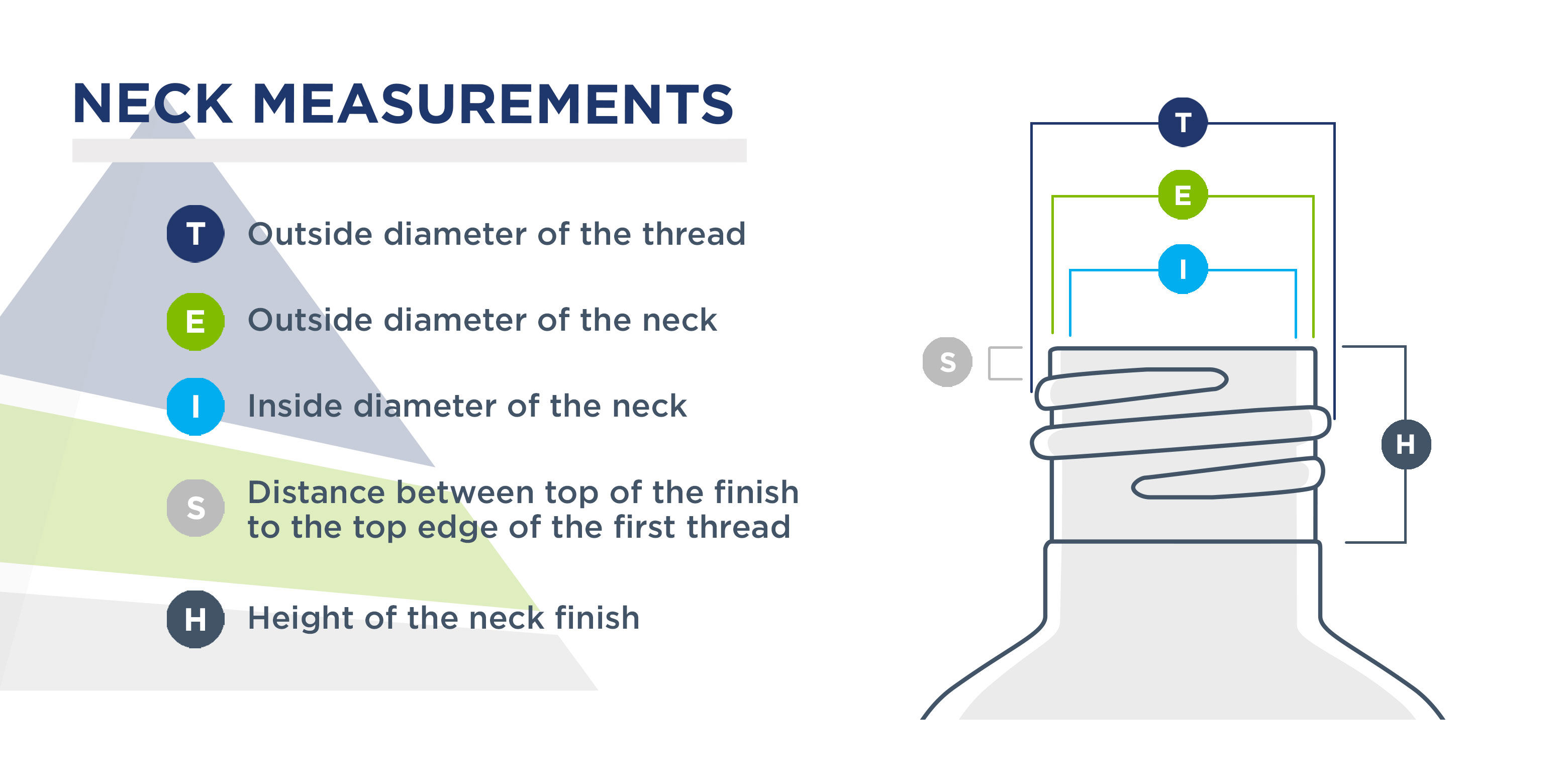

“T” Dimension

The “T” dimension measures the outside diameter of the thread. This measurement determines the closure counterpart for the bottle.

“E” Dimension

The “E” dimension measures the outside diameter of the neck. The thread depth is determined by the difference between “E” and “T” divided by two.

“I” Dimension

The “I” dimension measures the inner diameter of the bottle neck. Specifications for “I” are required at the very minimum for sufficient clearance for filling tubes. Linerless closures with a plug or land seal and dispensing plugs and fitments require a controlled “I” dimension for proper fit.

“S” Dimension

The “S” dimension measures from the top of the finish to the top edge of the first thread. This measurement is the key factor to determine the orientation of the closure and the amount of thread engagement between the bottle and the cap.

“H” Dimension

The “H” dimension is the height of the neck finish. This is measured from the top of the neck to the point where the diameter “T” (the outside diameter of the thread) extends down to where it intersects with the shoulder.

Continuous Thread Finishes

A continuous thread finish can be found on glass, metal, and plastic containers. This common thread type can be identified by the threads that wrap around the neck of the container continuously without any breaks in the thread.

400

A 400 neck finish indicates one thread turn.

410

A 410 neck finish indicates one and a half turns.

415

A 415 neck finish indicates two thread turns, but the threads are thinner and the neck is typically taller.

425

A 425 neck finish indicates two thread turns but is most commonly found on smaller-capacity containers such as vials.

430

A 430 neck finish indicates one or two thread turns. The threads are deeper than the uniform standard 400 and 415 neck finish. This unique neck shape is known as a buttress and is designed to help the user pour product with better accuracy.

DBJ

A DBJ neck finish is a tamper-evident screw cap for dairy, beverage, and juice. This neck features a ring beneath the threads that catch on to a detachable ring of a DBJ cap. When the user unscrews the cap from the container for the first time, the ring will break off from the cap, making it tamper-evident. This closure is not recommended for carbonated products, hot-fill applications, nitrogen gas-injected applications, or freezing.

Common GPI/SPI Bottle Neck Finishes

The Glass Packaging Institute (GPI) and the Society of Plastics Industry (SPI) created a set of guidelines to establish standards for threading on containers. The criteria for these standards consist of thread turns, the distance between threads, height, top beads, and continuous vs non-continuous threads. In addition to the neck width, the thread style for both the container and the closure must match to ensure a proper seal. The guideline also covers jar thread finishes.

Common Bottle Thread Sizes and Dimensions

18-400

A common neck finish found on glass bottles like the boston round dropper or euro-dropper, which are popularly used for essential oils and other oil-based products. This neck size is often paired with rubber bulb droppers and phenolic caps to ensure oils are securely sealed in the bottle.

20-410

A common neck finish found on mainly plastic bottles. This neck finish is found mostly on smaller size bottles ranging from 1oz to 4oz in the boston round, imperial-cosmo, bullet round, and cylinder round shape. However, a wide selection of caps and closures can be paired with a 20-410 neck size, including continuous thread caps, fine mist sprayers, disc caps, flip-tops, polytops, yorker tips, and more.

24-410

A common neck finish found mainly on plastic bottles but is becoming more available in aluminum as the demand for sustainable materials continues to grow. This neck finish is found in a variety of bottle sizes ranging from 2oz to 16oz and is common in the boston round, imperial-cosmo, woozy, bullet round, and cylinder round shapes. A wide selection of caps and closures can be paired with a 24-410 neck size, including continuous thread caps, fine mist sprayers, disc top caps, flip-tops, dispensing pumps, polytops, yorker tips, and more.

28-410

A common neck finish found mainly on plastic bottles but becoming more readily available in aluminum as the demand continues to grow. This neck finish is found in a variety of medium bottles ranging from 8oz to 32oz and is common in the boston round, imperial-cosmo, modern round, bullet round, and cylinder round shapes. A wide selection of caps and closures can be paired with a 28-410 neck size, including continuous thread caps, trigger sprayers, disc top caps, flip-tops, dispensing pumps, and more.

38-400

The most versatile closure neck size, this common neck finish is found on plastic, metal, and glass bottles. This neck finish has the largest selection of sizes ranging from 4oz to 1 gallon and is common across a variety of bottle shapes, including packer, sauce, cylinder round, honey bear, f-style, cubitainer, and industrial jugs. Due to the medium to large sizes of bottles with 38-400 neck sizes, the selection of closures is limited to standard continuous thread caps, child-resistant closures, and a few dispensing options such as yorker spouts and flip-top caps since products paired with these bottle sizes are typically more viscous liquids like honey or solid capsules for the smaller bottle sizes and higher volume liquids for the large 1-gallon sizes.

38-430

A common neck finish found mainly in the food and flavorings industry. This neck finish is typically only found on buttress bottles, specially designed with a unique shape and lip-to-pour product. Only a buttress cap will match a buttress bottle with a 38-430 neck finish. Buttress bottles are most common as 32oz, but smaller sizes can be sourced.

45-400

A common neck finish found mainly in the pharmaceutical/nutraceutical industry on packer bottles. This neck finish is common for the 175 cc to 400 cc in both plastic packer bottles and glass packer bottles. Continuous thread closures to fit the 45-400 threads is standard for the packer bottle.

53-400

The largest neck size for bottles, this neck finish is mainly found in the pharmaceutical/nutraceutical industry on plastic packer bottles. This neck finish is common for the 400 cc to 950 cc packer bottle sizes in both plastic and glass. Continuous thread closures to fit the 53-400 threads is standard for the packer bottle.

Determining the Best Packaging Solution for Your Business

The packaging industry is constantly innovating and looking for new ways to meet consumer needs. This guide is meant to be a tool to provide an introduction to the complex world of neck finishes. However, there are many more neck finishes available to accommodate specific types of closures. Contact us to speak with one of our friendly packaging experts today to find out what kind of bottle neck finish is right for your product.

Kristy is a marketing professional in the packaging industry since 2016. With a background in design, she has worked with brands of all sizes to identify their packaging needs by providing insight with market trends and industry knowledge.

Read More

For over forty years, Paramount has been delivering perfectly integrated packaging and supply chain solutions.