KNOWLEDGE

Resin Packaging Types and Popular Uses

The world is filled with plastic, an extremely versatile and useful material. As demonized as it’s become in recent years due to its negative impact on our planet, plastic is here to stay, for better or for worse. Plastic has enabled many of our advances and conveniences as a society which leads us to a point that is regularly overlooked: there are many different types of plastics in this world.

One of the core ingredients in all plastic products is resin and knowing which type of resin is right for you is key when it comes to production. Here we’ll dive into what plastic resin is, the different types, and its common uses.

What Is Plastic Resin

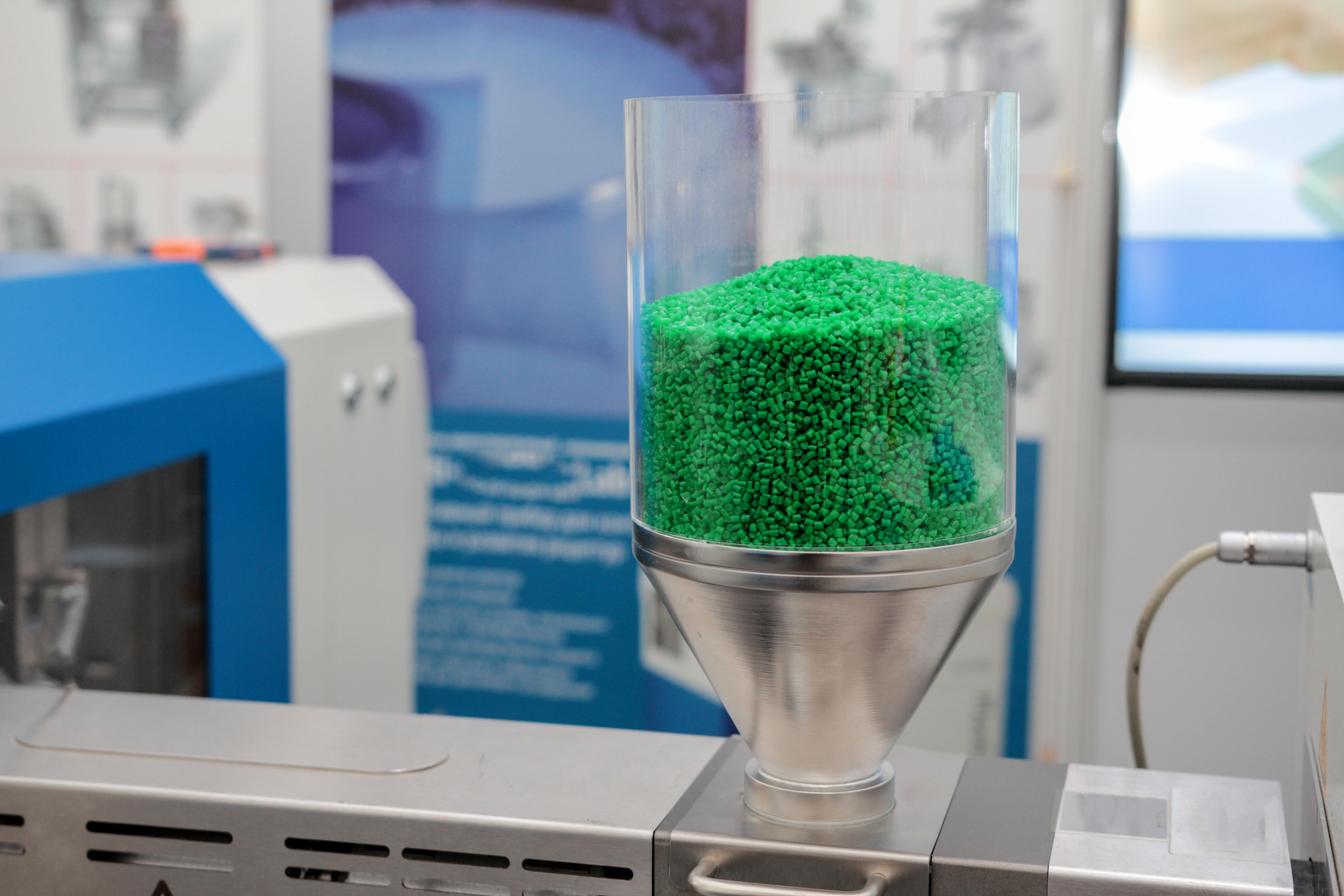

Plastic resin is a widely used material in the packaging industry. It’s lightweight, highly durable, and cost-effective. But what exactly is plastic resin? Plastic resins are made by heating hydrocarbons in what is known as the cracking process. Through this process, larger molecules are broken down into ethylene, propylene, and other types of hydrocarbons. The amount of compounds produced during this process depends on the cracking temperature.

When the cracking process is complete, the compounds are formed into chains known as polymers. This is where the process of making plastic can be altered in a variety of ways by combining different polymers with additives to make different kinds of plastic resins. The additives added during the polymerization process are what alter the properties of the plastic even further.

How well a plastic hardens, resists heat or exposure, to even its color or absorption properties is often determined with additives. Even with all these additives, once crushed into beads, these plastics are called resin. These plastic resin beads are then added to a plastic molding or baking process to create all the plastic products you see today.

What’s the difference between resin and plastic?

There is natural resin and plastic resin. Natural resin is composed of natural organic substances that are formed from plant secretions like tree sap that make amber. However, in this article, we are specifically talking about plastic resins.

Resin is defined by Merriam-Webster as any large class of synthetic products that have some physical properties of natural resins but are different chemically and used chiefly in plastics.

Plastic resins are considered industrial raw materials and plastic is the finished product. As we mentioned above, plastic resin is formed into beads that are sent to manufacturers to get melted, molded, formed, and reproduced into the many different plastic products that are part of our daily lives.

Resin Packaging Types and Popular Uses

According to Allied Market Research, the global plastic resins industry was estimated at $403.1 billion in 2019 and is expected to hit $522.5 billion by 2027. Due to the increasing use of plastics in the automotive industry, the rise in the usage of polyethylene terephthalate (PET) resins, and new end-use applications of plastic resins have accelerated this growth in the global plastic resins market.

One plastic resin stands out among the rest in this growing market, and that is polypropylene (PP). In 2019, PP products contributed to more than one-fourth of the global plastic resin market and are expected to dominate the market by the end of 2027.

Types of Resin Packaging & Common Uses

Plastic resins break down into seven major types, although the last one is more of a catch-all category. These categories are listed by their numerical plastic recycling code, they are:

- PET or PETE (Polyethylene Terephthalate)

- HDPE (High-Density Polyethylene)

- PVC (Polyvinyl Chloride)

- LDPE (Low-Density Polyethylene)

- PP (Polypropylene)

- PS (Polystyrene)

- Other/Miscellaneous

Each one of these plastic resins has different physical characteristics, different end uses, and varying degrees of recyclability.

Type #1 Polyethylene terephthalate or PET

PET or PETE (or the obsolete PETP or PET-P) is part of the polyester family. It is commonly used for beverage bottles and many injection-molded consumer product containers. PET can be semi-rigid to rigid and is very lightweight. PET is strong, impact-resistant, naturally colorless, and transparent. It is an excellent barrier to oxygen, water, and carbon dioxide. Cleaned, recycled PET flakes and pellets are in high demand for spinning fiber for yarns and producing fiberfill and geotextiles.

Common uses

Plastic bottles for soft drinks, water, juice, sports drinks, mouthwash, and condiments, cooking oil bottles, jars for peanut butter, jelly, jams, and pickles, products containing essential oils, alcohol beverage bottles, space blankets, and microwavable food trays.

Type #2 High-density polyethylene or HDPE

HDPE is made from petroleum and is the most widely used type of plastic. It has a stronger intermolecular force and tensile strength than low-density polyethylene (LDPE). It can also withstand high temperatures. Unpigmented bottles are translucent with good barrier properties and are well suited for packaging products with a short shelf life such as milk. HDPE also has good chemical resistance and is therefore used as packaging for many household and industrial chemicals like detergents and bleach. Pigmented HDPE bottles have better stress crack resistance than unpigmented ones.

Common uses

Milk jugs, distilled water, large vinegar bottles, grocery and retail shopping bags, cereal box liners, liquid laundry detergent, dish soap, fabric softener, motor oil, antifreeze, bleach, and lotion bottles.

Type #3 Polyvinyl chloride or PVC

PVC is a thermoplastic that is odorless, rigid, brittle, and generally white. It is the third most widely used plastic in the world after PET and PP. PVC is made by reacting chlorine, carbon, and ethylene (a petrol product). It is widely used in applications that require durable, long-lasting, waterproof, and weather-resistant materials making it the predominant choice in home construction. PVC is ideal for storing shampoos, oils, and other chemicals. PVC bottles are durable for long periods and can withstand various environmental demands.

Common uses

Chemical spray bottles, pipes, electrical wire insulation, clothing, bags, upholstery, tubing, flooring, waterbeds, pool toys, blister packs, clamshells, shrink wrap, deli and meat wrap, and tamper-resistant shrink bands.

Type #4 Low-density polyethylene or LDPE

LDPE is made from oil. Its tensile strength and density are lower than high-density polyethylene (HDPE), but its resilience is higher. LDPE is primarily used in film applications due to its toughness, flexibility, and relative transparency, making it a popular choice for use in applications where heat sealing is necessary. But it can only withstand low temperatures. LDPE is also used to manufacture flexible lids, bottles, wires, and cables. It has excellent resistance to acids, bases, and vegetable oils.

Common uses

Dry-cleaning bags, produce bags, trash can liners, food storage containers, bread bags, squeezable containers, six-pack soda can rings, food storage, shrinkwrap and stretch film, coatings for paper milk cartons, and hot and cold beverage cups.

Type #5 Polypropylene or PP

PP is the second most widely used plastic in the world. It is a low-density, stress-resistant thermoplastic made from a propene (or propylene) monomer. PP has a high melting point, it can be heated to its melting point, chilled, and then reheated again without any significant deterioration. This and the fact that it will liquefy instead of burn when subjected to high temperatures are what make PP a popular choice for manufacturing processes like injection molding. PP is widely accessible and cost-effective. PP is resistant to diluted chemicals making it ideal for liquid cleaning solutions.

Common uses

Bottle caps and closures, battery cases, pallets, hot beverage cups, disposable syringes, petri dishes, intravenous bottles, pill containers, car batteries, bumpers, automotive instrument panels and interior elements, car door trims, dairy tubs (e.g. sour cream, cottage cheese, margarine), condiment bottles, and takeout containers.

Type #6 Polystyrene or PS

PS is a versatile plastic from petroleum that can be rigid or foamed. Pure solid polystyrene is clear, hard, and brittle with limited flexibility. It can be cast into molds with fine detail. PS can be transparent or made in a variety of colors. It has a relatively low melting point and is often combined with rubber to make high-impact polystyrene for packaging. PS works well for durable applications that require toughness but not clarity. Typical applications include protective packaging, food service packaging, bottles, and food containers.

Common uses

Bottle caps, drinking straws, yogurt cups, vitamin bottles, cups, plates, bowls, cutlery, meat and produce trays, egg cartons, and hinged takeout containers (clamshells).

Type #7 Other/Miscellaneous

This is the catch-all category of all other plastics. Many biodegradable, photo-sensitive, and plant-based plastics are found in this category. Any plastic that is not HDPE, LDPE, PET, PVC, PS, or PP is put into this category. Additionally, any plastic resin type that has been developed since the original 6 resin types were established in 1988, is marked with the 7 or Other resin identification code.

As such, listing common uses for these kinds of plastics is nearly impossible since their applications and characteristics are so diverse, however, some items include bullet-proof materials, sunglasses, and DVDs.

Resin Packaging Ideas

Resin packaging can be made of any of the types of plastic resin listed above, but here is a list of some packaging ideas and what type of resin is generally used. Learn more about packaging materials or speak with a specialist to help you decide what resin is best for your product.

Rigid Plastics

Rigid plastic packaging is generally made from HDPE, PET, and PP. These types of packaging range from rigid plastic bottles and jars found on store shelves to industrial-sized drums. Plastic bottles and jars are most commonly made from PET and HDPE, but closures are made from mainly PP. Due to plastics’ versatility, plastic is identified as different resins for each type’s different properties and benefits. Other common types of rigid plastics include:

- butter tubs

- hummus, dip and spread containers

- industrial-size containers for the bakery, deli, seafood, and pharmacy departments at the grocery store

- yogurt cups

Plastic Film

Plastic films belong to a broad category of materials even though they’re generally lumped into one category grouping all flexible packaging together. The truth is that films can be made with different resins, each with a unique combination of properties that make them the right fit for specific applications. For example, LDPE acts as a gas barrier making it ideal for packaging food products that would spoil if exposed to oxygen.

Alternatively, PVC is gas permeable and ideal for packaging things like red meat which requires a small amount of oxygen inside the package to remain fresh. Plastic film can come in various colors, layers, printed or plain, and combined with other materials such as aluminum or paper. The only thing that plastic films have in common is that they are all flexible. Here we’ll break down the different types of plastic film even further:

Food Packaging Film

- produce bags

- non-frozen baked goods

- bakery bread and bun bags

- bags-in-a-box (boxed wine, etc)

- boil-in-bags (packaged food that is added to boiling water in its packaging)

- candy and confection bags and wrappers

- carton liners (cereal and cake box liners)

- hot dog wrappers

- bacon film

Non-Food Packaging Film

- industrial liners

- shipping bags (like for bark or mulch)

- bubble packing

- envelopes

- overwrap

- rack and counter bags

Other Packaging

- Stretch and shrink wrap

- Shrink wrap

Recycled Resin Materials

All the plastic products engineered today started as plastic resin pellets or beads. Considering the amount of plastic in the world today, the packaging industry is constantly challenged to find new ways to recycle plastic resin. The following is a list of products that recycled plastic resin can be used for once the material is ready for remolding:

- cleaning products

- foam packaging

- food storage containers

- lawn furniture

- medical equipment

- parts for transportation

- plastic bottles & bottle caps (for cosmetics, beverages, milk jugs, prescriptions, etc.)

- plastic bags & food wraps

- plastic lumber (for park benches, decks, fences, playgrounds, etc.)

- piping

- waste bins

- writing utensils

- & much more

Choosing the Best Resin Packaging for Your Products

At Paramount Global, our goal is to help businesses like yours thrive by providing an array of services to get your products to your customer in the most efficient way possible. Our specialists are experts at helping you find the right kind of packaging for your product. Contact us today to get started.

Hayley is a marketing professional and copywriter with a background in crafting content for a diverse range of industries. She has been writing about packaging and supply chain logistics for Paramount Global since 2022. She specializes in explaining complex topics in a clear and engaging way and is an advocate for sustainability in packaging and supply chain management.

Read More

For over forty years, Paramount has been delivering perfectly integrated packaging and supply chain solutions.