Guide to Tamper-Evident Packaging Solutions

When perusing products on store shelves, consumers want to be sure that the items they select are brand new and untainted. That’s where tamper evident packaging emerges as an effective solution designed to provide a clear indication if a product has been tampered with before purchase, instilling confidence and peace of mind in consumers.

In this guide we will explore what tamper evident packaging is, the benefits of tamper evident packaging, the different types of solutions available, and factors to consider when choosing the option that best suits your product.

What is tamper-evident packaging?

Tamper evident packaging is designed to alert consumers when a package has been opened. An open package can signal a variety of potential issues including the product being tampered with or premature product exposure to external elements that can expedite the product’s degradation.

With a focus on the container opening, tamper evident packaging is sometimes confused with tamper resistant packaging, specifically child resistant packaging. The difference between tamper evident and tamper resistant packaging is how easily the packaging can be opened. Tamper evident packaging is not designed with any resistance when opening, while tamper resistant packaging requires additional effort often with specific motions such as simultaneously pushing and turning which can be difficult for younger children to execute.

The main goal of tamper evident packaging is to provide a visual sign that the packaging has been opened. This means tamper evident packaging can be easily opened, but the feature that signals if the package has been unsealed will be difficult to replicate back to its original sealed form.

Importance of Tamper Evident Packaging

Tamper evident packaging is an important tool that provides a variety of benefits to both your product and the customer. The following highlights a few benefits of using tamper evident packaging.

###Product Safety

Tamper evident packaging provides an additional layer of product protection before reaching consumers. Consumers have been conditioned to avoid damaged products and tamper evident packaging provides a quick visual confirmation that the product integrity has not been compromised. This is especially important for consumable items that can adversely cause harm if contaminated or expired from premature unsealing. An intact tamper evident package provides peace of mind to consumers and appreciation for a brand that makes sure they are getting a fresh new product.

Consumer Trust

Utilizing tamper-evident packaging builds customer trust and loyalty by demonstrating a brand’s commitment to consumer safety. When customers see that a brand is taking steps to ensure their well-being through tamper-evident packaging, it instills a sense of confidence in the brand’s products. This conscious decision highlights the brand’s dedication to protecting customers against tampering, contamination, or unauthorized access, thereby enhancing transparency and authenticity. By prioritizing consumer safety, brands can cultivate trust and loyalty, as customers feel valued and secure in their purchase decisions.

Reduce Shipping Damage

Tamper-evident packaging provides an important solution that benefits consumers and helps companies reduce shipping damage. During the product’s journey, which involves multiple stages and potential risks, tamper-evident packaging adds an additional layer of security. It is a visible deterrent against tampering and unauthorized access, alerting shippers and recipients if the package has been compromised. Beyond tamper resistance, this packaging also offers physical protection, safeguarding the contents from impacts and external factors that could lead to damage during transit. By minimizing the occurrence of damage, businesses can decrease returns and replacements, ultimately saving costs and improving customer satisfaction. Tamper-evident packaging enhances product integrity and ensures that products arrive safely and intact, benefiting both businesses and consumers.

Types of Tamper Evident Packaging Solutions

When it comes to tamper-evident solutions, there is a wide array of options available to fit your product’s specific requirements. These solutions can encompass different elements within the packaging process, such as the use of specialized tapes or incorporating tamper-evident features into the container design itself, such as tear tabs and tamper-evident seals. To provide you with a better understanding, let’s explore some commonly used types of tamper-evident solutions.

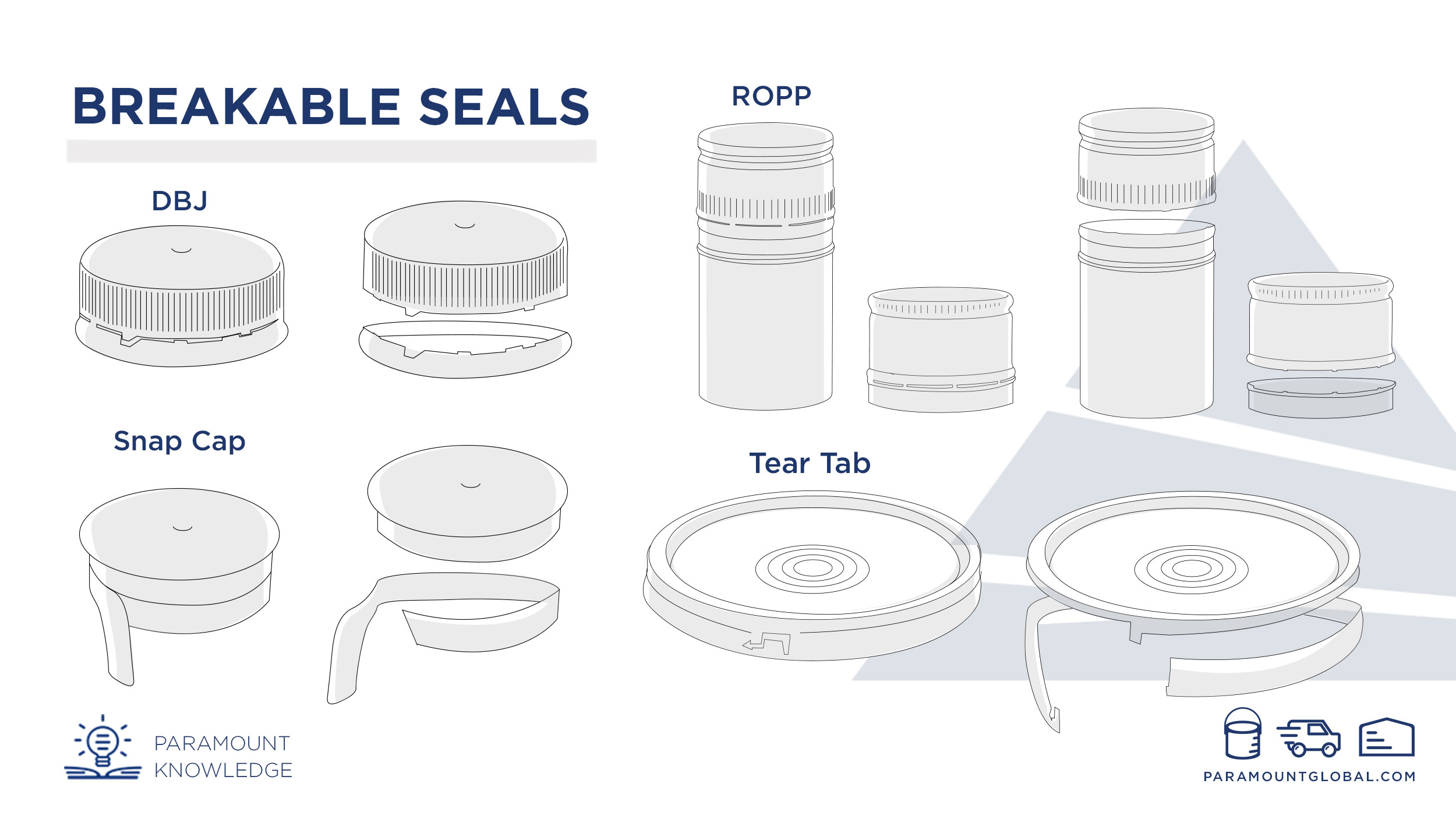

Breakable Seals

Breakable seals refer to tamper evident solutions that have components break off upon opening the package. Different types of breakable seals include tear tabs, snap caps, and DBJ closures. Each of these seals have components molded onto the closure that are broken off when the the product is opened. For example, many juice and dairy products use a DBJ closure that features a band that breaks off when unscrewing the cap for the first time. While tear tabs and snap caps require users to pull off a tab before the package can be unsealed for opening. All these designs promote breaking a part of the closure to show tamper evidence since it is impossible to reattach the pieces once broken.

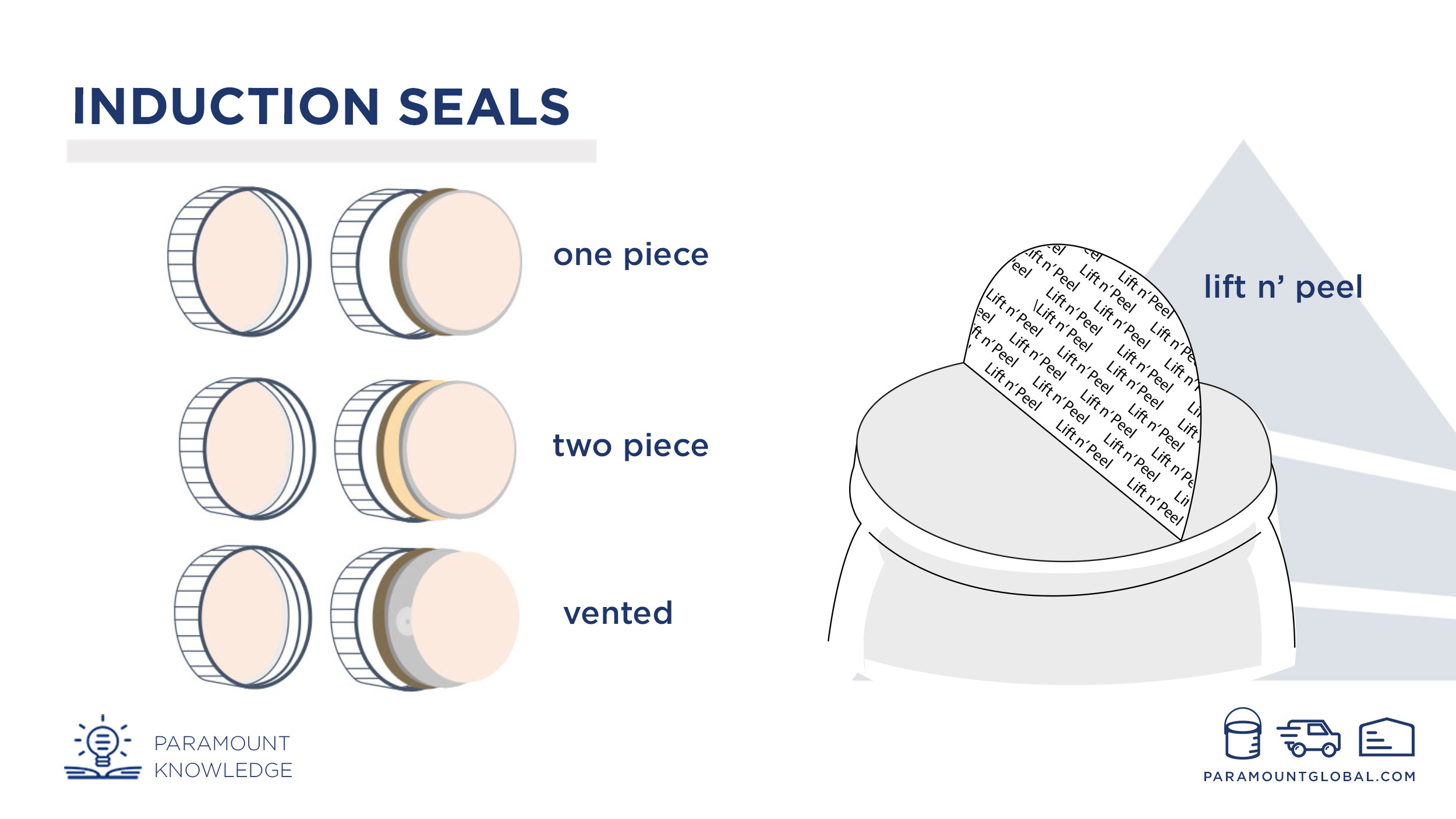

Induction Seals

Induction seals are one of many different types of liners that can be found inside of a closure. Induction seals rely on heat to melt the adhesive from the liner and pressure to create an even seal on the lip of a container. The liner serves to seal the product inside the container and can be composed of a variety of materials for different barriers to accommodate the product’s properties. The seal’s adhesive provides tamper evidence since a user must peel the seal off when using the product for the first time. Similar to other tamper evident solutions, an induction seal may leave residue behind when peeled off the surface it was adhered on. The most noticeable feature of tamper evident induction seals is the difficulty of resealing the liner once it has been peeled off. It is nearly impossible to reuse an induction seal once peeled since the adhesive needs specific heat and pressure which can only be executed by a machine for a proper seal. A bonus feature of induction seals is a message printed on the liner to notify the user that the product has been sealed for their protection or instructions on how to remove the seal. These printed liners are often called ‘lift n peel’ or ‘sealed for your protection’ induction seals.

Label Seals

A label consists of a paper material with adhesive on one side to stick onto the surface of a container. Label seals are used as a method to identify tamper evidence. Similar to tape, when a label is removed from the surface it is originally applied on, often a sticky residue remains after removal or part of the label may stubbornly cling on to the surface of the packaging. Adhesives of varying strength can be used for different levels of tamper evidence. In addition to providing tamper evidence, branding or safety messages can be printed on the label which the user must tear through when initially breaking the seal.

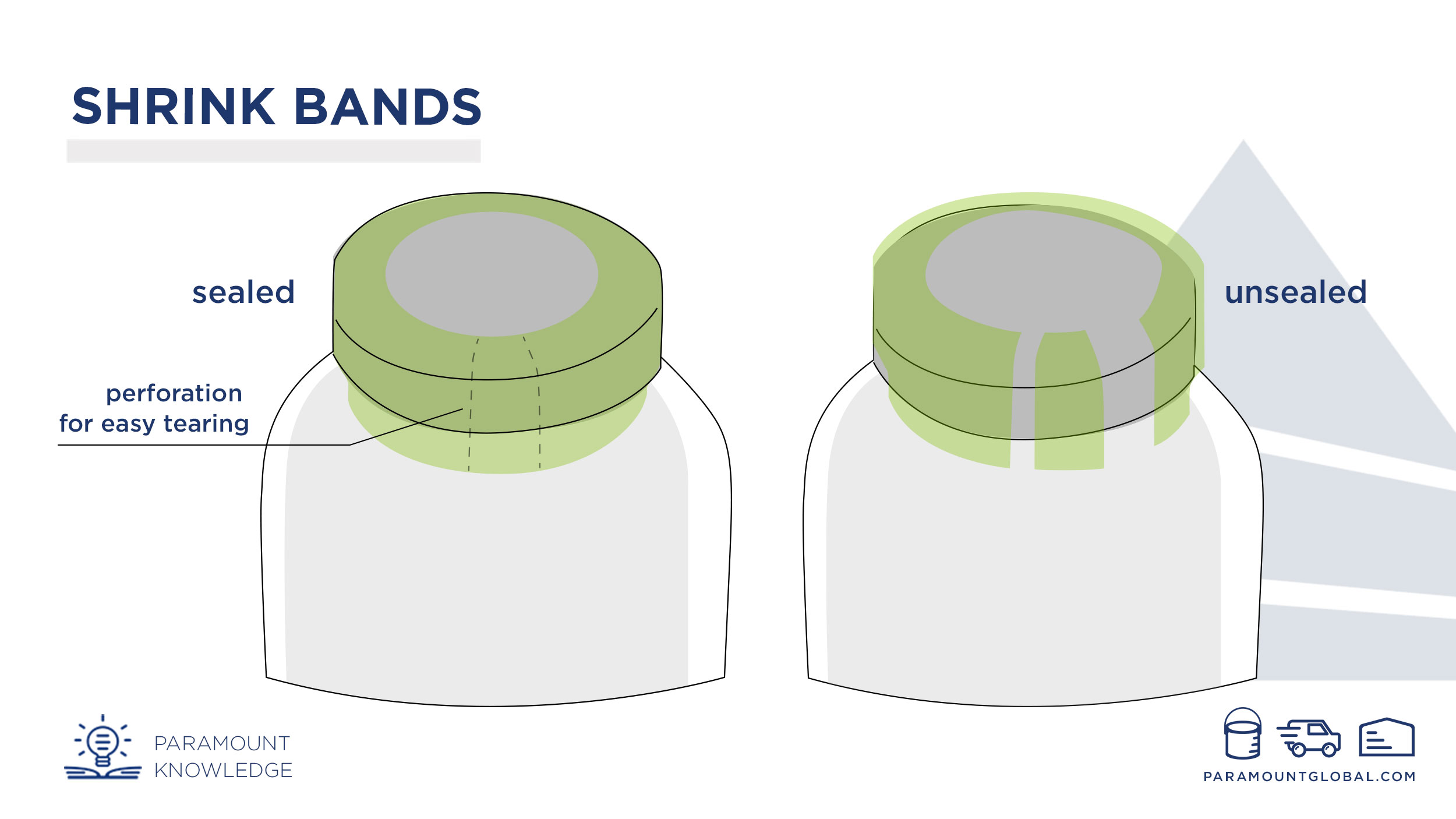

Shrink Bands

Shrink bands consist of a thin plastic strip that wraps around a closure and container. The plastic is heated to shrink down and securely tighten over both packaging components. A user must tear the shrink band to access the product inside. Sometimes there are small perforations on the band that allows the user to easily tear off the wrap, but once torn, it is impossible to reassemble back into its unsealed form. A step up from shrink bands is a shrink sleeve which wraps the entire container and closure while also providing a tamper evident solution.

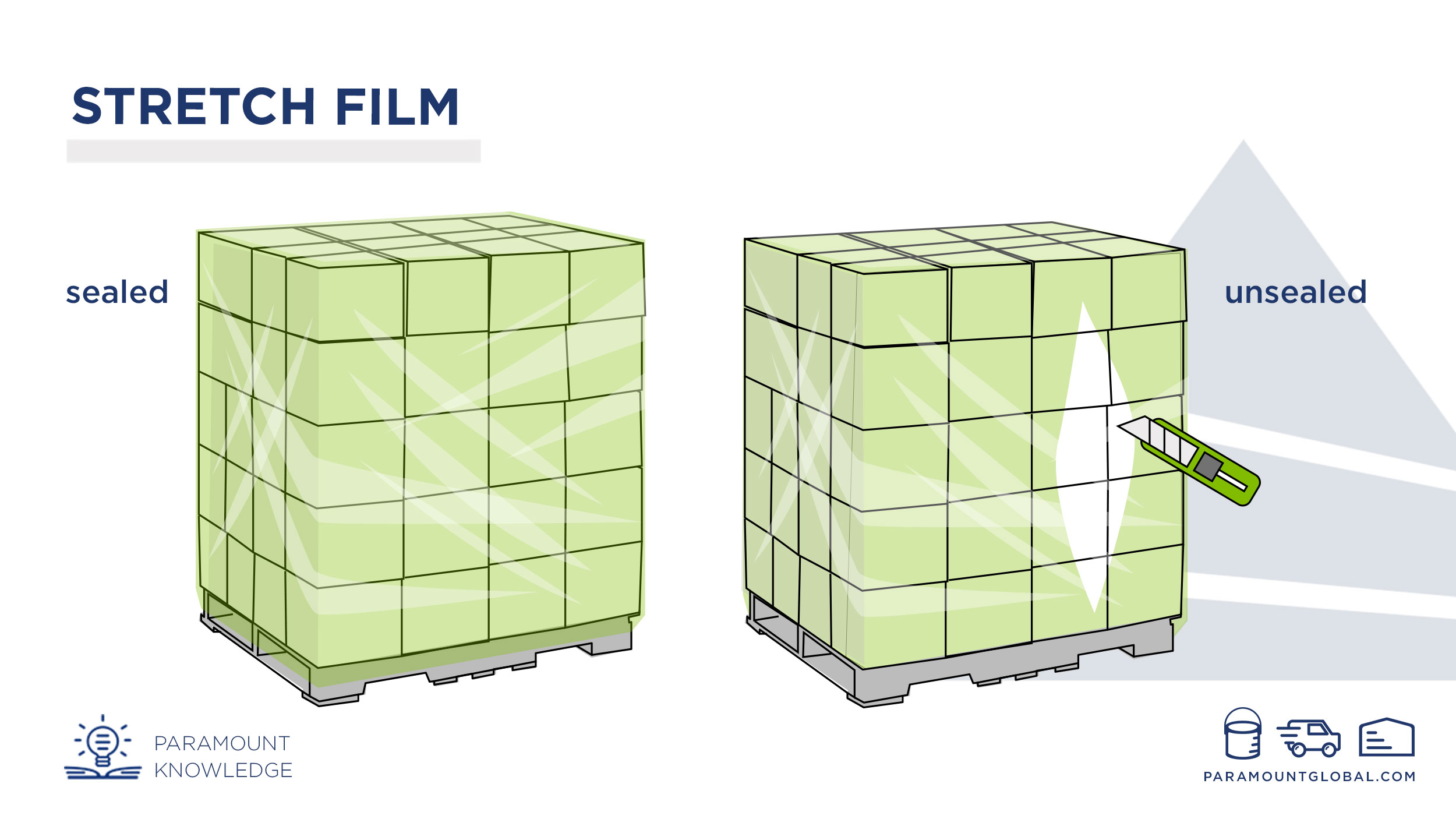

Stretch Film

Stretch film is commonly used for securing bulk quantities of product on a pallet for shipping. The thin film is stretched multiple times around the product on a pallet to securely hold the items in place and prevent shifting during transportation. Due to the thin properties of the film, when wrapped multiple times, it creates a thick layer of plastic that becomes difficult to unravel. To access the product packaged with stretch film, you must cut or tear through the film, allowing it to provide a layer of tamper evidence.

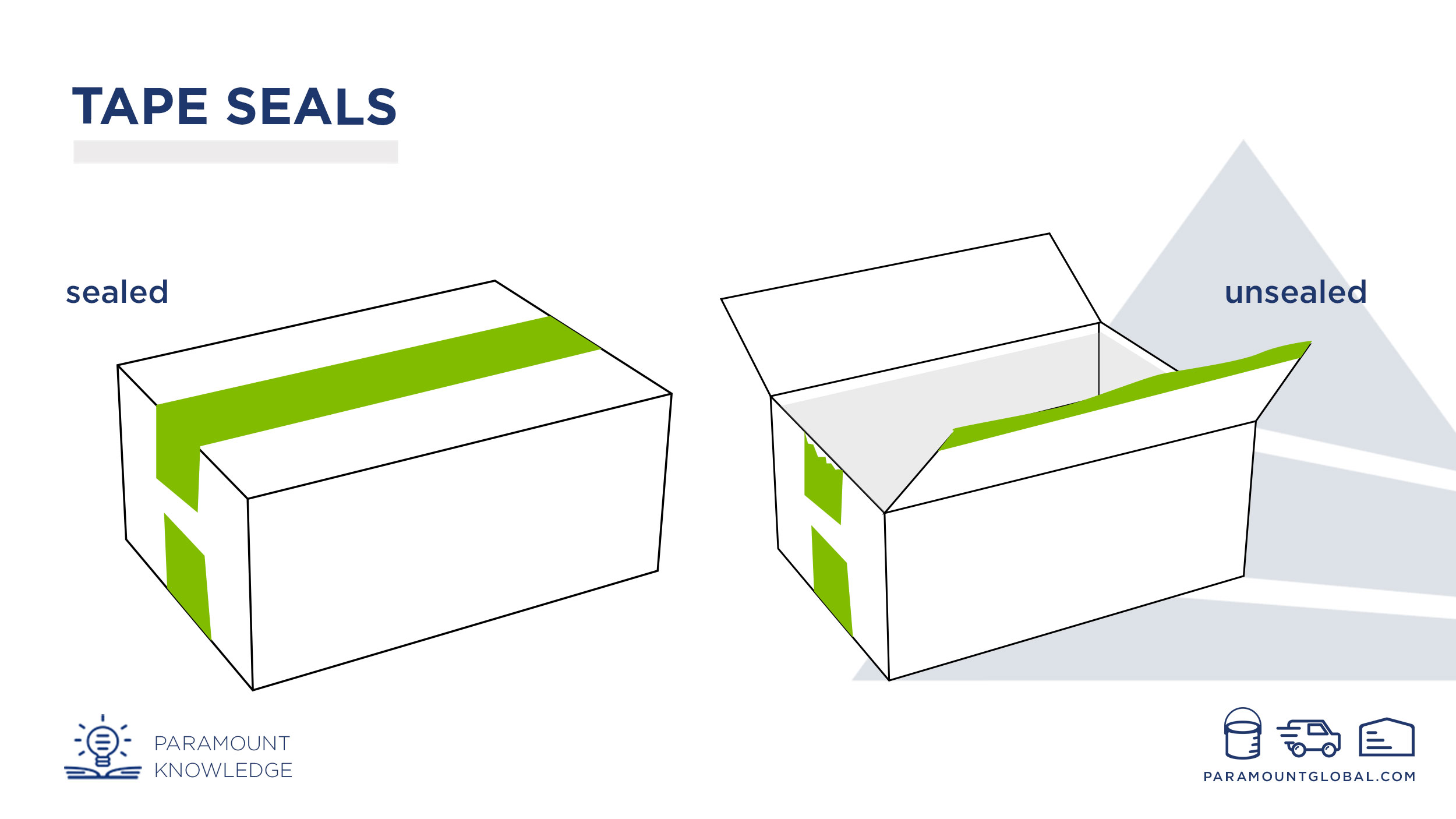

Tape Seals

Tape seals serve as an effective tamper evident solution for securing packaging and ensuring their integrity. These seals are designed to provide visible evidence of tampering attempts. When applied to packaging, tape seals form a strong adhesive bond that is difficult to remove without leaving behind a clear sign of tampering, such as a broken seal or sticky residue. Adhesives of varying strength are options for different levels of tamper evidence and seal integrity. However tape seals are more often used for making sure a product is safely sealed in its secondary packaging instead of being solely used as a tamper evident solution.

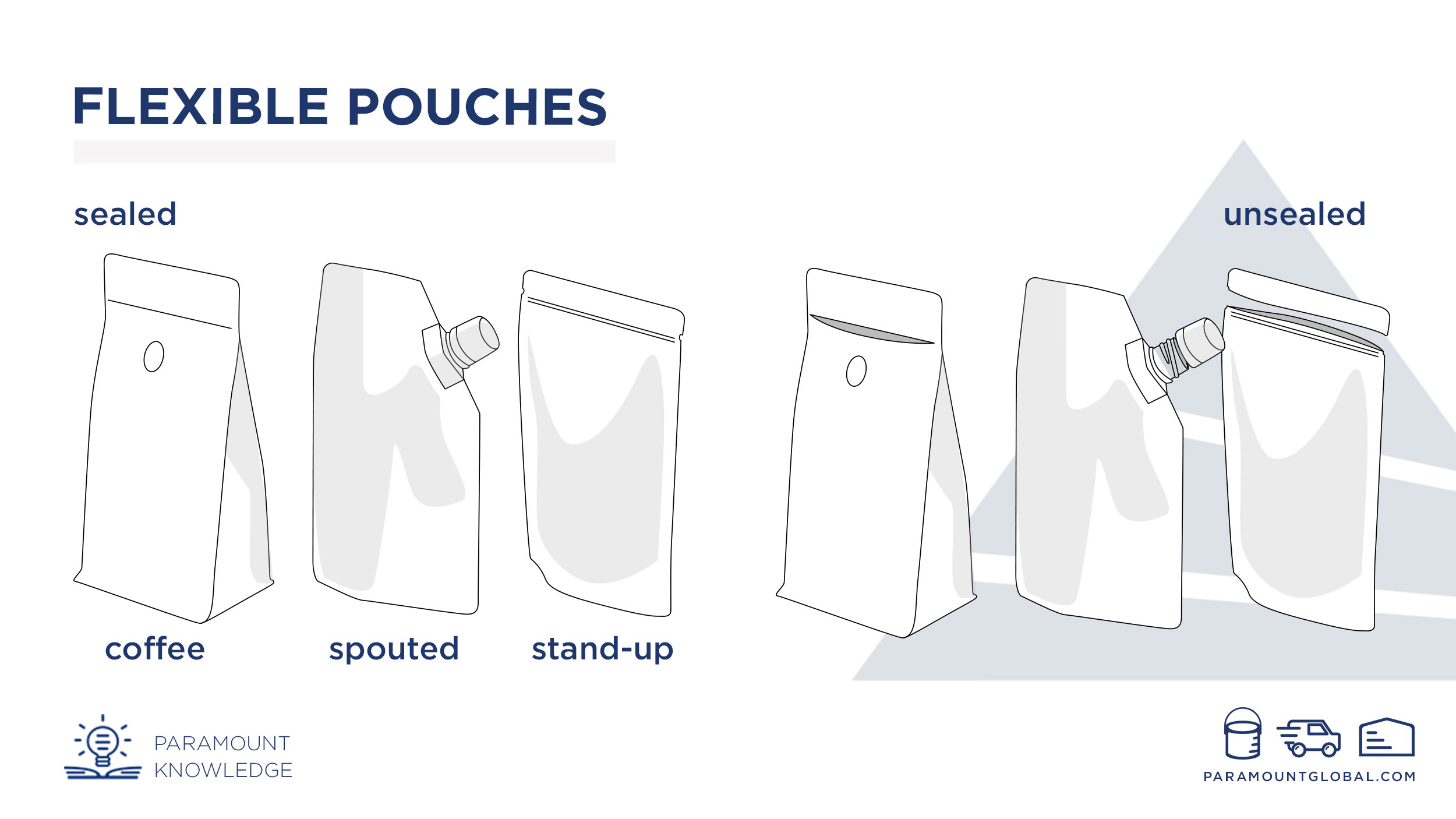

Flexible Pouches

Flexible pouches are a popular tamper evident solution especially in the food industry. Many flexible pouches often have a resealable function to allow users to continue using the package until all the product has been consumed. Whether the pouch has a resealable option or not, pouches are designed for users to tear the top when first opening the package. Once the top is torn, it is difficult to seamlessly reattach the torn off piece which creates a visual for tamper evidence.

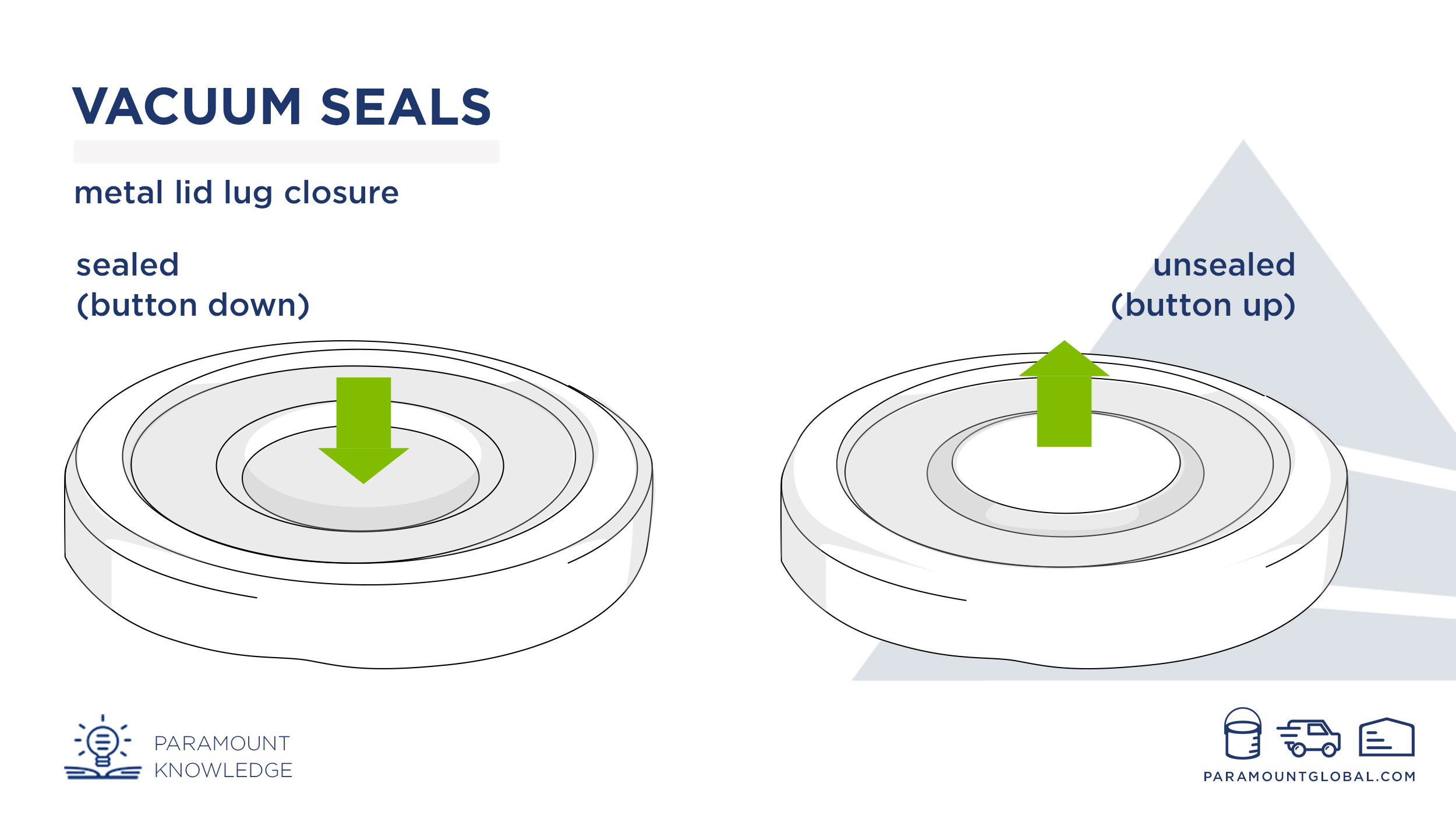

Vacuum Seals

Vacuum seals serve the dual purpose of preserving freshness and providing tamper evidence, particularly when used with lug closures. Lug closures are commonly used for achieving airtightness, especially with preserved foods. One notable characteristic of lug closures is the distinct popping sound they produce upon initial opening after sealing, serving as an indication that the container has remained unopened since sealing. In addition to this, lug closures often feature a button that visually confirms if the airtight seal has been broken. Brands utilizing a lug closure with a button may include a warning to users that if the button has popped up, the seal has been broken. Once the original vacuum seal is broken it becomes impossible to reseal the cap in a depressed position. For lug closures without a button, resealing the lid and subsequently reopening the container will no longer produce the audible sound of escaping air.

Applications of Tamper-Evident Packaging

Tamper evident packaging is a helpful tool for brands to show customers their product is safe and untouched prior to purchasing. The following highlights the types of tamper evident packaging used in different industries.

Pharmaceutical and Healthcare

Safety is of utmost importance in the pharmaceutical and healthcare industry, where products often contain ingredients that can rapidly degrade upon opening. Consumers seek assurance that the products they consume will improve their well-being rather than pose a risk due to tampering. To address this concern, tamper evident solutions such as shrink bands, induction seals, and label and tape seals are widely used for medicines and medical devices. These solutions not only provide tangible protection but also serve as a marketing tool, allowing brands to showcase the additional safety measures they have implemented to earn customer trust and guarantee the integrity of the purchased products.

Food and Beverage

Tamper-evident packaging plays a vital role in the food and beverage industry, ensuring food safety and protecting consumers from potential hazards or contamination in food products. It offers clear indications if a product has been tampered with, enabling manufacturers to detect any tampering that may have occurred during transit or storage. Tamper evident packaging also serves as a valuable marketing tool, instilling greater confidence in consumers regarding the quality and safety of the products they purchase.

Industrial

While tamper evident packaging is less prevalent for consumer industrial products, it is still utilized within the industrial industry, particularly in the supply chain. Tamper evident measures are frequently used to verify the integrity of ingredients and components received prior to assembly. For instance, shrink wrap and tape are commonly used to securely package components for shipping, serving the dual purpose of safeguarding against damage and providing tamper evidence, assuring that the components remain intact and unaltered throughout transportation and storage.

Personal Care and Beauty

Maintaining customer loyalty in the personal care industry requires brands to meet the high expectations of discerning customers. To ensure the safety and integrity of their products, tamper evident packaging is used to prevent contamination or damage. Since personal care products are often designed for absorption into the body, tampering poses significant health and safety risks. By utilizing tamper-evident packaging, brands effectively demonstrate their commitment to product quality and reassure customers that the contents remain untainted.

How to Choose the Right Tamper Evident Packaging Solution

The goal of using a tamper evident solution is to protect your product and the consumer. The following walks through a range of factors to consider when selecting a tamper evident packaging solution for your product.

Identify Your Product and Its Risks

Understanding your product is the first step to choosing any type of packaging. Being familiar with the ingredients and formulation will help you identify the best packaging for your product. It’s important to understand the properties of your ingredients and what they may be susceptible to. Elements such as oxygen and light can cause a product to break down faster. Tamper evident packaging allows brands to effectively communicate their efforts to reduce these risks by assuring consumers that the product they received is securely sealed for both freshness and safety.

Evaluate Available Solutions

Once you have identified the risks to your product, the next step is to assess the available solutions for mitigating those risks. Certain tamper evident solutions are tailored for specific products, like DBJ closures which are designed specifically for beverage bottles. On the other hand, there are alternatives for different product types, such as using shrink bands or resealable flexible pouches for packaging food items.

Choose the Right Type of Tamper Evident Solution

Your final selection should depend on the desired functionality of the tamper evident solution for your end users. Take into account the consumer’s experience and how they will engage with your product. Consider whether the evidence of tampering will be easily detectable, and ensure that any intrusion is clearly identifiable.

Consider Costs and Feasibility

Considering the various options for tamper-evident solutions, it’s important to note that price points will vary. Basic tape and shrink wrap, primarily used for sealing and securing packaging, provide a fundamental level of tamper evidence without incurring extra costs, but they are not consumer-oriented solutions. However, tamper-evident packaging designed for consumers is readily available, albeit with additional expenses for customization or decoration. Regardless, the investment in tamper evident packaging is reasonable when weighed against the potential harm to a brand’s reputation caused by customers receiving a product that has been tampered with.

Compliance Requirements

Certain industries must exercise more caution when selecting their packaging solutions and will frequently opt for tamper evident packaging to ensure compliance with safety regulations. This is particularly crucial in mitigating the potential risks associated with consuming defective or contaminated products. The FDA mandates tamper evident solutions as a requirement for certain products’ packaging. It is essential to be well-informed about any compliance requirements pertaining to your product so you can factor that into your packaging solution.

Implementing Tamper Evident Packaging Solutions

Tamper evident packaging solutions are used throughout the supply chain before the final product reaches the end user. It’s important to make sure materials and ingredients are securely transported through each stage of the product journey to deliver a final product that meets customers’ expectations. The following methods can assist you in implementing tamper evident packaging solutions into your operations.

Establish Operating Procedures

Common warehouse consumables like tape and stretch wrap offer a level of tamper evidence, allowing for quick identification of potential product tampering through visual inspection of any damage to these components. Tampered components within a packaging solution can compromise the overall integrity, resulting in potential damages that can be financially burdensome for a brand. By implementing operating procedures that include thorough inspection for tamper evidence, it becomes possible to prevent damaged components from moving through the supply chain and being incorporated into poorly constructed products that could negatively reflect on your brand.

Train Employees

Once opportunities have been identified to implement checking for tamper evidence in your operations, make sure your employees are trained to identify signs of tampering. Visual examples to help employees recognize the potentially damaged products are an extra layer of quality control that will ultimately benefit the end user.

Perform Quality Assurance Checks

Tamper evident packaging is designed to help users quickly identify any potential damage or tampering of the product. Including routine quality assurance checks in your quality control checklist can enable you to detect any underlying issues within your supply chain that might compromise the integrity of your tamper evident packaging. Audits and inspections can also be implemented for an extra layer of quality assurance. Tamper evident packaging will help you achieve quality control goals your customer expects with your product.

Protect and Enhance the Safety of your Products Today

Choosing the best tamper evident packaging solution to protect and enhance the safety of your products can be challenging to navigate with all the options available. Finding a partner with experience working with brands in your industry can help provide guidance on what best suits your product.

At Paramount Global we partner with brands to provide tamper evident packaging solutions that work best for their product’s needs. We focus on supplying tamper evident systems such as closures, matching containers, and flexible pouches. We also have a global network of partners to provide additional tamper evidence solutions such as shrink bands, custom label seals, and more. Together we can coordinate a complete packaging supply chain to help you reach your packaging goals and deliver a high-quality product to your customer. We’re committed to delivering innovative packaging solutions and establishing a lasting partnership to help you grow. Contact us today to learn more about tamper evident solutions and how we can partner with you!

Hayley is a marketing professional and copywriter with a background in crafting content for a diverse range of industries. She has been writing about packaging and supply chain logistics for Paramount Global since 2022. She specializes in explaining complex topics in a clear and engaging way and is an advocate for sustainability in packaging and supply chain management.

Read More

For over forty years, Paramount has been delivering perfectly integrated packaging and supply chain solutions.