KNOWLEDGE

Your Ultimate Guide to Bulk Packaging

Bulk product packaging plays a crucial role in protecting products during transportation and storage, creating brand recognition, and influencing customer perception, making it a vital step in any successful business strategy.

In this ultimate guide, we’ll help you understand everything you need to know about bulk product packaging and the steps to take in order to package your products efficiently. No matter what you sell, this ultimate guide to product packaging will help you take your business to the next level.

What is Bulk Packaging?

Bulk packaging is a type of product packaging that typically deals with bulk shipments or shipments that are going to intermediate locations. The packaging that is used in bulk packaging needs to be designed, evaluated, and produced in a specific process to deliver a great experience and fulfill your goals.

The first step to identifying the type of bulk packaging needed is understanding your user. Is the bulk packaging for an end consumer or is it for an intermediate location such as a filler or product distributor? The packaging of a bulk option for your end consumer to purchase in-store will look very different from the packaging used to safely deliver product formula to your contract filler.

Common Types & Examples of Bulk Packaging

Let’s explore a few of the most common types of bulk packaging that you can expect to work with when starting the process.

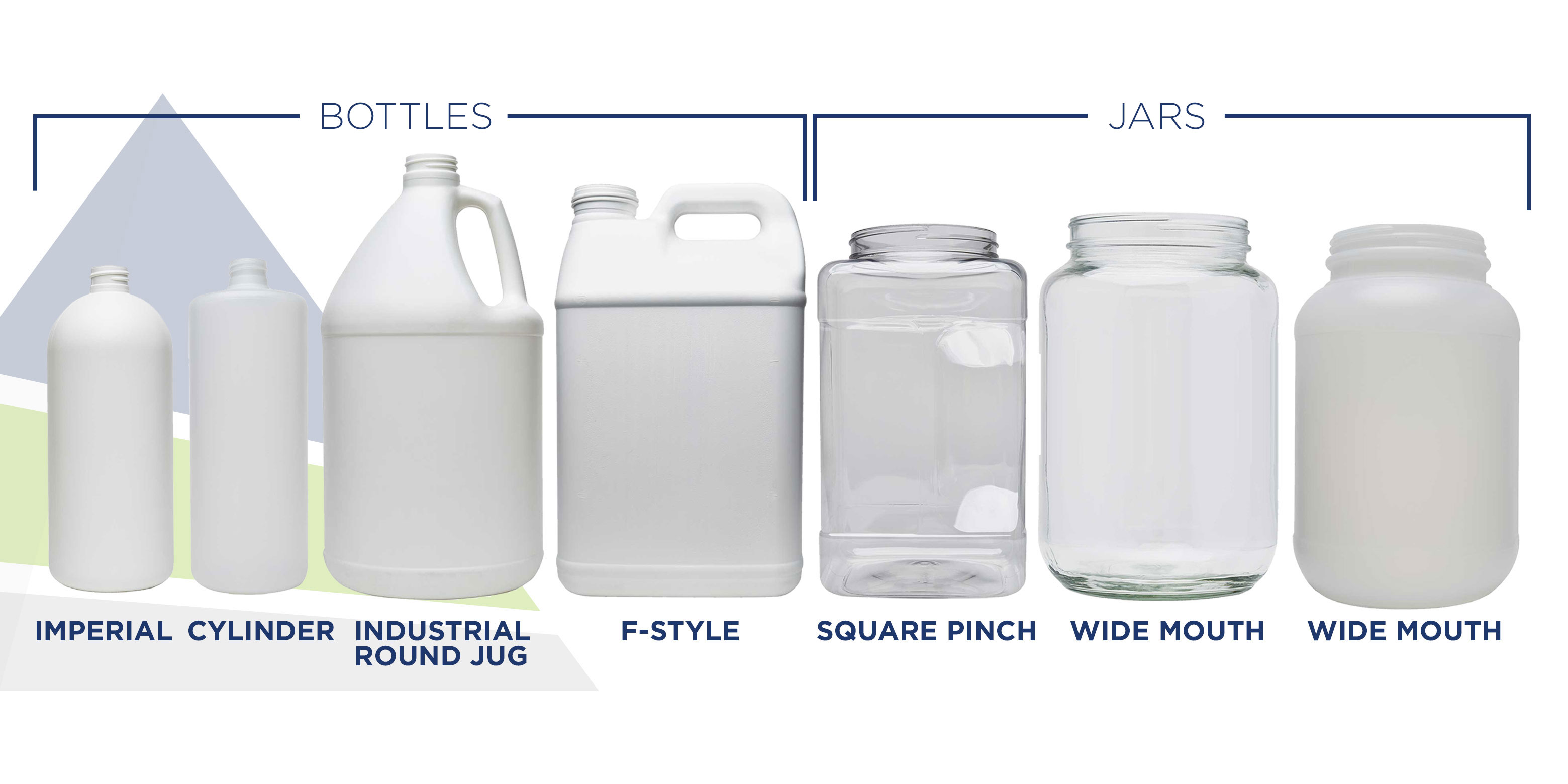

Bottles & Jars

Moving a consumer product into a bulk option helps provide cost savings to consumers and also extends brand loyalty to the product since the user has more products to use for a longer period of time. Bottles and jars are available in larger sizes ranging from a quart to 2.5 gallons. Plastic bottles and jugs such as industrial round jugs or f-style jugs, which have built-in handles are the most common option available when the container is larger than 1 gallon since the quantity of product becomes more difficult to handle because of its weight. The larger the container, the fewer stock packaging shapes are available, but customizing is an option that companies can use to maintain their brand when converting their product into a bulk option.

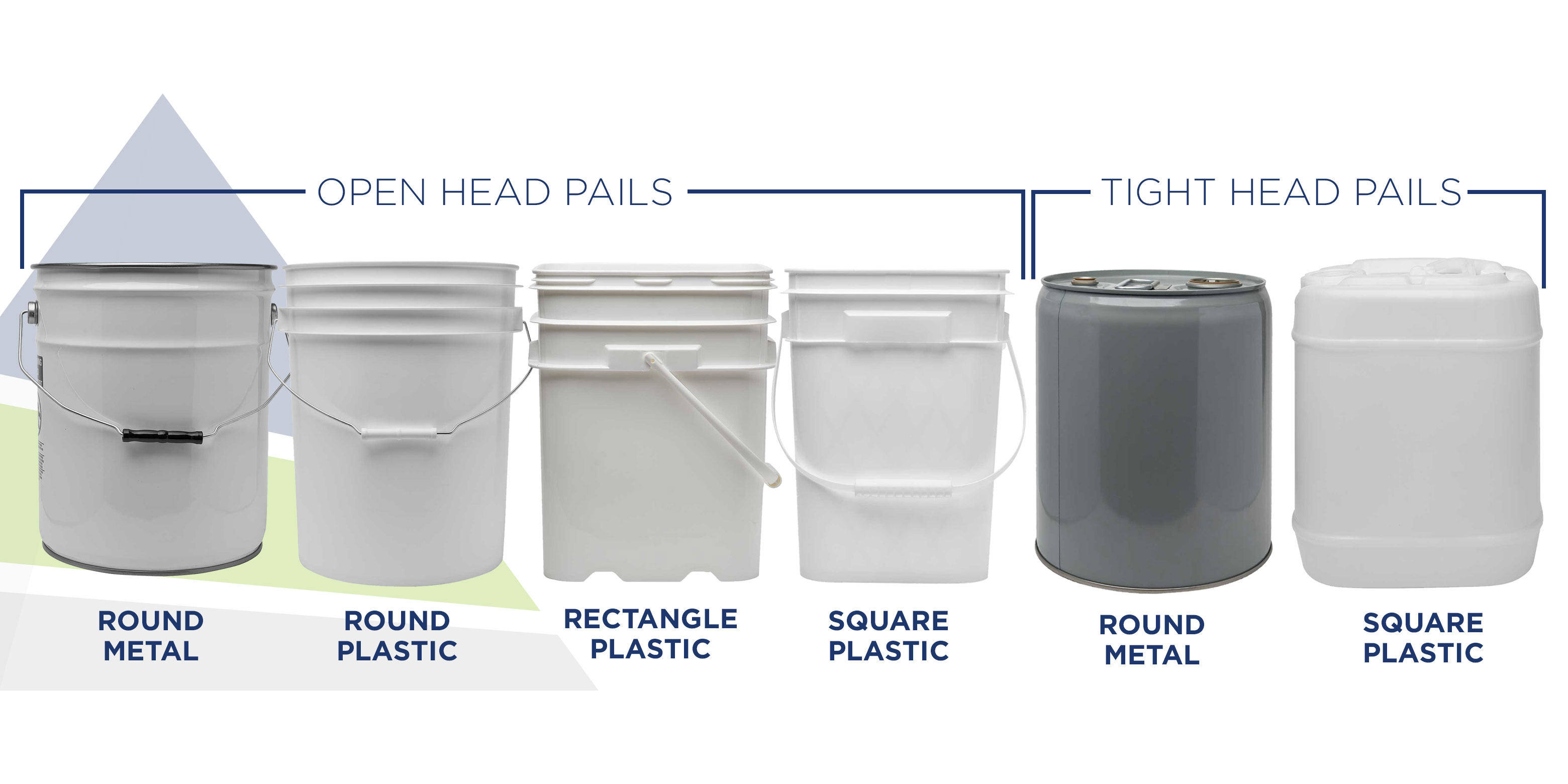

Pail Buckets

Another common type of bulk packaging is pails and buckets. Available in plastic or steel, the durable material can withstand extreme conditions, accommodate liquid or solid products, and can be used for hazardous materials and products. Pails are available in shapes that can be optimized for palletizing and can be certified with a UN Rating to meet shipping regulations. Many pails are designed with handles to aid users with carrying a full container of products. Pails can be found on store shelves for industrial-type products such as adhesives, paints, coatings, and chemicals. For businesses, pails are used across a variety of industries ranging from food to chemical because of their versatility.

Drums

Similar to pails, drums are versatile for packaging a variety of bulk products. Drums are available in plastic, steel, and fiber. Plastic and steel drums can store a range of product types and can also be certified with a UN rating for transporting hazardous products. Fiber drums are best used for bulk dry products such as powder. Drums are mainly used for transporting bulk volumes of ingredients or materials and are not commonly used to package consumer products.

IBC Totes

The largest type of bulk packaging available is an IBC (Intermediate Bulk Container) Tote for liquids. IBC totes are most commonly available in the 275-gallon size and are typically composed of a steel cage around a rigid plastic tank. Totes can also be made from all steel or plastic. Totes are designed for functionality and can often be reconditioned for reuse at a lower cost compared to purchasing a new tote. IBC Totes are most commonly used for transporting bulk industrial chemical-type products and can also be UN Rated to accommodate hazardous products.

Corrugated Boxes

When it comes to bulk packaging, corrugated boxes often fulfill the role of secondary packaging as an additional layer of protection. Corrugated boxes use fluted corrugated sheets along with flat liner boards which provide more support and cushion than a typical chip paperboard box. Different thickness options are available depending on your product’s needs. For example, heavier products will need thicker corrugated walls or additional reinforcement inserts to maintain the box’s integrity during transportation.

Why Is Properly Packaging Products Important?

Those who are new to packaging might wonder why it’s so important, even when it comes to bulk. After all, isn’t the packaging just a way to ship products? The reality is that packaging is more than just a box to get products from one location to another. Here are a few of the reasons why packaging is so important:

Protect Products During Shipment

Choosing the right type of material for your bulk packaging is essential. In addition to the primary packaging that contains your product, it’s important to also consider your secondary packaging (such as the box that will ship your containers of product). Packaging materials protect and secure products for transportation and storage. No matter how fragile your product is, you can find the right type of packaging to ensure it gets to its final destination in one piece. On the other hand, the wrong type or lack of packaging can damage products and cause them to be sent back.

Provides a Cost-Effective Solution

Another important reason to bulk package products correctly is to save money. Fewer materials are needed when packaging in bulk. Bulk packaging helps maximize space during shipping, which can save a few cents on every load and make a big difference to your bottom line. By exploring your packaging options and finding the right solution, you can help reduce the cost of materials and shipping to improve your budget for packaging in the future.

Works as an Extension of Your Marketing

Packaging allows you to communicate directly with your customers. Messages, graphic designs, and marketing copy is still a vital element of packaging design, even for bulk products. As long as a product is consumer-facing, marketing design needs to be utilized for competing with other brands on the shelf.

Defines and Highlights Your Brand

Your brand is an important part of your business. It’s what makes you unique from competitors and provides recognizability to your audiences. Applying your brand to bulk packaging is one of the best ways to convey your branding to customers and vendors. The colors, design, type of material, and layout of packaging all work together to communicate your brand and make it an iconic standout on the shelves.

Assessing Your Product and Business Needs for Packaging

As you begin the bulk packaging process, there are a few key steps that you need to follow. The first is to actually assess your product and your business needs for bulk packaging. You can’t go into packaging blind, so take a step back and actually examine your product needs. There are two main factors to keep in mind:

Product Details

The first factor to consider is product details. Do your products require any type of special packaging? Are they fragile or sensitive in any way? Do they need to meet certain temperature conditions? And how long will your product be stored before it is set out on the shelves or shipped to consumers? All of these questions can help you examine your products carefully and determine the specifics that will come into play as you design your packaging.

Buyer Details

It’s also important to remember your buyer and what they expect out of product packaging. A buyer can be defined as an end consumer purchasing your product off a shelf or a vendor distributing your products who may have strict policies on how your product must be packaged to fit their shelves. Additional questions to consider when understanding the buyer perspective include: Are they ordering direct online, or will your product go to retailers and resellers? If your product is displayed in a physical location, what section of the store will it be in? What other products will be around it? The buyer perspective is a great way to understand what buyers and consumers expect from your products and what type of packaging or information is important to them.

Measuring Your Product Dimensions

The next step in the bulk packaging process is to identify the product dimensions for your primary and secondary packaging. This is an important step as it will help you figure out what size packages you need. It will also help you determine what will be most cost-effective for shipping and storing your products.

Keep in mind the ways in which customers will order products from you. When they order multiple products, what kind of package do you want those to be delivered in? How can you package products together to save money, and what type of dimensions will those bundles have? This can help you save money and deliver a better product experience to your customers.

Choosing the Right Packaging Design

For consumer bulk packaging, the design of your packaging is one of the most important steps in the process. This is where your creativity and ingenuity can come into play. You want to make sure the design fits with your brand and communicates the message you want to convey to customers. A larger volume of the product means more weight for the end user to handle. An additional detail to consider is how to enhance the user’s experience with design features such as an integrated handle or a view stripe to see how much product is left. The complete packaging design must evolve to accommodate a different user experience when it comes to bulk packaging.

Assessing Bulk Packaging Costs

After you’ve put together the design you want for your packaging, you can then assess the complete packaging costs. The main function of bulk packaging is to maximize the amount of product while reducing cost.

As with any type of packaging, the more customized your packaging is, the more expensive it is likely to be. Both the time it takes to manufacture custom packaging and the price of materials contribute to high packaging costs. Understanding your priorities and parameters will help narrow down the best options to work with.

Consider Going Green with Your Bulk Packaging

Oftentimes, we think that being environmentally friendly and “going green” means being more expensive. However, the opposite can be true. Bulk packaging can align with sustainability goals by reducing the amount of material needed to package your product which contributes to a reduction in carbon emissions and waste that damages our environment.

Another benefit of keeping sustainability top of mind when building your packaging solution is the impact it has on customers. Consumers like knowing that they are purchasing from a company that respects the environment and prioritizes sustainable packaging. They also like knowing that their purchase isn’t adding damage to their surroundings. Aligning with customer values can help increase brand awareness and loyalty.

Choosing a Reliable Packaging Supplier

Finally, it’s important that you have the right partner by your side for your bulk packaging process. You’ll want to find a packaging supplier who can help you throughout the process and help you reach decisions that support your goals. The right partner will help you find cost-effective options while helping you come up with creative and forward-thinking design solutions. They’ll also keep you informed when pricing changes or when a new opportunity arises.

Paramount Global is a reliable packaging supplier that can help you find the required materials needed for your bulk packaging solutions and improve your overall packaging process. Our complete supply chain solution takes the burden of packaging off of your shoulders and gives you peace of mind. When we become a member of your team, we’re there every step of the way to help you achieve your packaging goals. Contact us to learn more and see how we can enhance your bulk packaging experience today.

Hayley is a marketing professional and copywriter with a background in crafting content for a diverse range of industries. She has been writing about packaging and supply chain logistics for Paramount Global since 2022. She specializes in explaining complex topics in a clear and engaging way and is an advocate for sustainability in packaging and supply chain management.

Read More

For over forty years, Paramount has been delivering perfectly integrated packaging and supply chain solutions.